Grubbicon

New member

Yesterday I put my track bar on temporarily. I ended up just tacking the factor mount back on the frame and the mount artec supplies for the axle in the kit. That should allow me to come up with the measurements I need on the driver side and then just replicate it for the passenger side. Then after the passenger side tower is in make a permanent mount for the frame side.

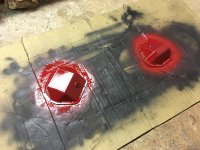

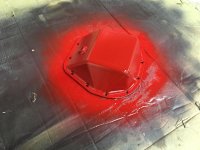

My Ruff Stuff diff covers also showed up today. Here is the picture of the one for the sterling.

My Ruff Stuff diff covers also showed up today. Here is the picture of the one for the sterling.