WJCO

Meme King

Dude, thats awesome! congrats! going to be a real nice set up!!

Congrats! Looking forward to seeing how it all comes together

Thanks guys. Just have to figure out the steering.

Dude, thats awesome! congrats! going to be a real nice set up!!

Congrats! Looking forward to seeing how it all comes together

Ordered the ProRock today! Thanks to Steve at Dynatrac who was very helpful in making this happen.

View attachment 223549

I do need some help regarding the steering. I am probably going to have to make a custom drag link. To start with the drag link assy will be about an inch longer. The knuckle end will be a typical hi-steer JK.

The end at the pitman arm will be WJ. The upper link for WJ and JK is different. The JK not only has larger thread diameter doing in to the drag link sleeve but also has a larger and different stud taper that meets the pitman arm. I DO NOT want to ream the pitman arm. I want to leave the pitman arm and the upper link as a WJ style. I think I may just take the parts down to a machine shop and have a custom adjustment sleeve made. Anyone else have any other ideas? I want to be able to retain the adjustment sleeve to center the steering wheel without disconnecting ends.

Nice!! Now you can get that steering attenuator you always wanted.

Nice!! Now you can get that steering attenuator you always wanted.

Sweet! No thoughts on steering issues but pumped to see what you figure out

This is awesome :thumb: Congrats man!

Congrats. Are the mounts the same for a wj and jk? I always wondered if j could put my front axle order my wj

Nice man! Take some pics during the install

I've got a few ideas in my head but not exactly sure. I may wait till I get the axle too and really look at ideas. I'm really considering just buying a Snyergy drag link and cutting the upper end and threading it for the WJ link. But I hate to spend the money if I'm not completely sure it will work.

Thanks.

Call Synergy...I've worked with them before for steering components for three rigs...they are very receptive and helpful

Thanks. To the best of my knowledge, the only mounts re-used are the upper mounts on the axle that connect to the upper control arms. So you would have to cut the JK brackets off your axle and weld on WJ ones. It would be a pain. The biggest difference is the coil perches. The WJ ones are not only in different spots as far as distance to the knuckles, but they also sit forward on the axle. The coil spring is centered about 2 inches in front of the axle instead of centered right on the tube. Then you have to deal with the ABS and brake hoses and other little stuff. Also, the WJ uses a 1310 drive shaft as well. This will be a learning experience for me as well setting this all up. Dynatrac is basically building me a JK everything axle, with the Clayton WJ brackets.

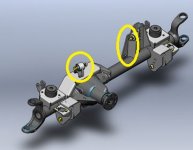

In the picture below, it shows all the WJ brackets on the JK44 axle. I will not be using the upper mounts pictured nor that truss thing that goes over the pumpkin. Dynatrac will use their own JK ones.

View attachment 223686

Ordered the ProRock today! Thanks to Steve at Dynatrac who was very helpful in making this happen.

View attachment 223549

I do need some help regarding the steering. I am probably going to have to make a custom drag link. To start with the drag link assy will be about an inch longer. The knuckle end will be a typical hi-steer JK.

The end at the pitman arm will be WJ. The upper link for WJ and JK is different. The JK not only has larger thread diameter doing in to the drag link sleeve but also has a larger and different stud taper that meets the pitman arm. I DO NOT want to ream the pitman arm. I want to leave the pitman arm and the upper link as a WJ style. I think I may just take the parts down to a machine shop and have a custom adjustment sleeve made. Anyone else have any other ideas? I want to be able to retain the adjustment sleeve to center the steering wheel without disconnecting ends.