You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail Ready Beadlock Wheels Installation Write-Up

- Thread starter wayoflife

- Start date

JeepJeep75

New member

Well that's interesting... I haven't seen Trail Ready BL's in person up close yet. I just assumed that any aluminum wheel that had a bolt going into it via a gorilla (that's me!) turning it would have a replaceable insert for said bolt. [emoji848]

Sent from my iPhone using WAYALIFE mobile app

Just curious, is TR the only beadlocks offering that backspacing?

The only other wheel I was considering was the KMC Enduro which you can get in a 17x8, with 5.48" and blank so that you can have your own bolt pattern drilled. For the money, the Trail Ready was a better bet and I really like how they look.

I'm pretty sure Hutchinson rock monsters you can get in the BS if not damn close.

You can get them in an 8-lug too a 4.5" and 5.28" which is really close. While I really LOVE the way Hutchinson's look, they're tough to install and I'm not real fond of how they tend to leak air.

Can't agree more about the ease of install. These took me about 30 mins each with 40" nittos versus 45-50 mins each with kmc machetes and coopers.

I really like these a lot just can't wait to see them on the Jeep!

That looks really sharp in red like that - nice job :thumb:

Well that's interesting... I haven't seen Trail Ready BL's in person up close yet. I just assumed that any aluminum wheel that had a bolt going into it via a gorilla (that's me!) turning it would have a replaceable insert for said bolt. [emoji848]

You'd be surprised at how many aluminum bead lock wheels don't have inserts. Even with inserts, you need to be careful with torque as you can spin them as well. The bigger concern is galvanic corrosion and that is why it is important to use zinc plated bolts.

JeepJeep75

New member

Well, I have learned a few things today about beadlocks. [emoji106]

Sent from my iPhone using WAYALIFE mobile app

Sent from my iPhone using WAYALIFE mobile app

Destroyer

New member

mastrcruse

New member

I'm looking to start my install next weekend and had a quick question about TPMS sensors. I'd like to still be able to see the PSI in my tires, I like that feature, so I was wondering if you think I could make that work or give up on that dream? I know a guy locally is running his OEM sensors and valve stems but he is running the small rings and I ordered the larger rings. . Whats your thoughts? Thanks!

Btw...this thread is going to really make the install easier so I appreciate your write up!

Btw...this thread is going to really make the install easier so I appreciate your write up!

Last edited:

HighwayTrout

Hooked

I'm looking to start my install next weekend and had a quick question about TPMS sensors. I'd like to still be able to see the PSI in my tires, I like that feature, so I was wondering if you think I could make that work or give up on that dream? I know a guy locally is running his OEM sensors and valve stems but he is running the small rings and I ordered the larger rings. . Whats your thoughts? Thanks!

Btw...this thread is going to really make the install easier so I appreciate your write up!

Didn't we go over this already?

mastrcruse

New member

Didn't we go over this already?

Oh F'ck yeah we did haha. Been a long week. I even made a thread about it...holy shit I must be getting old.

Last edited:

SSRuger

Member

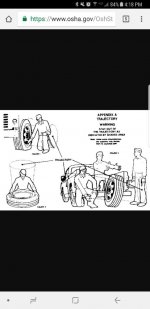

I'm pretty sure you are supposed to stand in th line of roll when servicing tires. I know a beadlock/tire combo for a jeep probably isn't gonna have enough pressure to really do much damage, but I've seen plenty of aircraft wheels blow out sideways.

Sent from my SM-G955U using WAYALIFE mobile app

jeeeep

Hooked

View attachment 275216View attachment 275217

I'm pretty sure you are supposed to stand in th line of roll when servicing tires. I know a beadlock/tire combo for a jeep probably isn't gonna have enough pressure to really do much damage, but I've seen plenty of aircraft wheels blow out sideways.

Sent from my SM-G955U using WAYALIFE mobile app

I put a couple of ratchet straps in a cross pattern (+) on my 37's when I filled them to set the rear bead

aTX427

New member

That looks really sharp in red like that - nice job :thumb:

You'd be surprised at how many aluminum bead lock wheels don't have inserts. Even with inserts, you need to be careful with torque as you can spin them as well. The bigger concern is galvanic corrosion and that is why it is important to use zinc plated bolts.

Would you recommend applying anti-seize to the Chamber II bolts during installation?

Would you recommend applying anti-seize to the Chamber II bolts during installation?

Negative. You need to install them dry.

Sent from my iPhone using WAYALIFE mobile app

JKbrick

Active Member

Uh oh, I put a small dab of anti seize on the bolts on my slabs

Sent from my iPhone using WAYALIFE mobile app

Uh oh, I put a small dab of anti seize on the bolts on my slabs

You're probably fine. Wet threads just require less torque than dry threads because of less friction. The torque spec for bead lock wheels is for dry.

Finn Sizzle

New member

Cindy and I recently installed an all new Dynatrac XD60 front axle in a 72.5" with PRO 1550 steering knuckles but to take advantage of all the benefits this new setup has to offer, we needed to run 40" tires mounted on wheels that have 5.5" of back spacing. Needless to say, we picked up a set of Cooper Discoverer STT Pros in a 40x13.50R17 and decided to run them on Trail Ready Beadlock wheels which are offered in an 8 lug bolt pattern and with the 5.5" of back spacing we needed. In this short write-up, you'll get to see just how easy it is to get everything installed and using basic tools.

Nice write up, thank you.

I just ordered the same on a set of PR60s. What size lugnuts did you use? I ordered the 2" long lugnuts and they appear to snug the rim tightly, however would like to go with a longer lugnut, maybe 2.5"+. Would like to know what lugnuts you are running on your wheels/axle combo. Thanks!

Last edited:

TrainWreck618

Caught the Bug

Nice write up, thank you.

I just ordered the same on a set of PR60s. What size lugnuts did you use? I ordered the 2" long lugnuts and they appear to snug the rim tightly, however would like to go with a longer lugnut, maybe 2.5"+. Would like to know what lugnuts you are running on your wheels/axle combo. Thanks!

I tried 2" lugs with the same combo and they wouldn't work, had to move to 3".

Sent from my iPhone using WAYALIFE mobile app

Clearskies

Caught the Bug

You have to keep chasing the bolts in a circle until they do

I found on the Trail Ready Beadlocks you have to tighten the bolts in a star pattern, otherwise as you go around the ring tends to pull a little to the side that's already tight and it's a bitch to get the socket in the hole to torque the bolts.

Finn Sizzle

New member

I tried 2" lugs with the same combo and they wouldn't work, had to move to 3".

Sent from my iPhone using WAYALIFE mobile app

Which 3" lug nuts did you go with? I've been searching around and having a hard time finding a set

Sent from my iPad using WAYALIFE mobile app