1 Ton Swap - Part 2 - Front SD60, Final Assembly & Install

With the axle set up it was finally time for some primer and paint!

After a few coats and drying overnight at the shop, I picked up the axle first thing in the morning to bring it home. Joe He-Man'd it up into the truck by himself. What a beast!

Back at home, and solo, I totally cheated and just used the cherry picker to unload it and get it under the jeep.

Things aligned well enough, but it is an absolute requirement that you have fully adjustable control arms with some decent misalignment joints. My EVO Long Arms were able to do the job but things definitely sit spread out given the wider axle position with brackets being more out-board.

With all the remaining parts on hand, it was time for final assembly. This was where I encountered my first issue - the Currie unit bearings. The fine print I didn't pay close enough attention to mentions that their 1-Ton UBs were based on 1999-2006 F350/F450 UBs. Unfortunately, my SD60 came out of a 2008, and had a slightly different hole alignment, so the Curries were out.

With no other real aftermarket solution readily available, I opted to go with a set of Raybestos "professional grade" UBs that were a few steps higher than OEM quality. They fit perfectly, and came with a pair of ABS sensors. The second thing I needed to do to make them work for my application was to have them re-drilled for an 8x6.5 lug pattern to match the 14b rear.

The reason I went this direction rather than redoing the rear to match the Ford 8x170mm pattern was for current and future wheel options. (The KMC Machete Crawl beadlocks I elected to run are not offered in 8x170mm)

Lucky for me, Busted Knuckle Offroad offers an inexpensive service to re-drill super duty unit bearings - so I ordered the Raybestos UBs off Rock Auto and had them shipped directly to BKO, who redrilled 'em and shipped them back to me, ready to install.

After installing the 35 spline 1541H shafts, the the new UBs mated perfectly to the Reid high-steer knuckles.

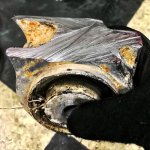

Let me take a moment, if I may, to call out how silly difficult the snap rings are on these SD axles. The ring itself is massive and requires a ton of force to pry. The amount of shaft you have to clear to get them recessed enough for the groove is so deep you need super long, super skinny pliers to even reach. I broke two of my cheap HF pliers trying to get them installed before I broke down and ordered the must-have Snap-On pliers apparently everyone must own to work on these things. And yes, my hands were so sore and tired from trying that I totally cheated and slipped some 1/4" pvc over the handles to give me more leverage. :sFun_hot:

With that out of the way the rest of the tasks were pretty straight-forward. The ABS sensors connected straight up to the JK harnesses. For the E-Locker, I discarded most of the wiring harness as I simply ran what was needed up to the SPOD and replaced the front ARB Locker slot with the Eaton.

For Brakes, I installed the "Z23 Evolution Sport Brake Upgrade Kit" from PowerStop, which came with calipers, pads and rotors. No issues.

The breather hose was an interesting nuance. The truss interferes with the existing hole, so you need to buy a few NPT bits to elbow in a re-route. Thankfully the Artec instructions tell you exactly what to get

New Warn Locking Hubs finished out the assembly and it was ready for wheels and tires!

The next task to was to figure out steering linkage. With the high-steer plate installed on the passenger knuckle, steering wheel centered, and the front tires on the ground with about 1/8" toe set, I took hole-to-hole measurements from the pitman arm to the knuckle for the draglink, and between the two lower knuckle holes for the tie rod.

Ruff Stuff Specialties makes a "GM Crossover Steering" kit which consists of beefy 1.5" X .25" Wall DOM tubing and 4 tie rod ends. The kit comes raw and disassembled, so you cut the tubes to length, then weld on the bungs. I opted to not use the TREs and instead go with high misalignment HEIM ends.

There was some drilling to get things to work. The pitman arm and knuckles needed to be bored out to accept the larger bolts for the HEIM ends. The knuckles were easy, but the forged pitman arm was a PITA to drill.

I took the newly assembled drag link and tie rod home and mocked it up, still straight as an arrow, just to see how much we would need to clear the Ballistic Fabs diff cover at full lock. The tie rod would for sure need a couple of bends to make it work, but nothing drastic, I think it was 10-11 degrees on 2 bends. The drag link, at full passenger lock, ever-so-slightly touches... so slight that I opted to leave it straight as it puts zero strain on the bar.

With the tie rod ends bent and dialed in, it was again time to prime and paint. (Note the pic below has the tie rod flipped to the underside of the knuckle for ease of on/off installation as it's a bit of a dance to get the bolts/nuts going on the passenger side knuckle)

At this point I took the time to align the jeep as best I could for the garage. Adjusted the track bar to get things centered, adjusted caster a decent amount, and got the toe in to 1/8". From there, I set up a fixed horizontal point off the axle to the tie rod, and turning the wheels lock-to-lock, I taped off and measured the throw needed for the Ram assist. I was previously running the West Texas Offroad Redneck Ram, which consists of a ram piston running off a tapped and rebuilt steering box. One of the issues I had on the JKX was that my piston kept weeping/leaking fluid, so because of that, and the fact that the new throw measurements were outside its spec, I opted to go with a new PSC ram.

With the PSC ram installed, it was just a matter of re-connecting the hydraulic lines and bleeding the steering, and we were in business with the complete new 1-ton front end!

Rear coming soon