You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cooper STT Pros and ATX Beadlocks.

- Thread starter LO_Rex

- Start date

So what’s a good inspection schedule. I live where it doesn’t snow so no salt on the roads. I understand that you check torque periodically, but how often do you back out the bolts and check for corrosion? Do you replace all the bolts when you get new tires? I’m curious as I’m considering beadlocks on my build, and want to understand the best practices to use. I don’t mind extra maintenance or service, just want a clear picture. Thanks!

Being that you live in CA. I wouldn't worry too much about it. I typically give my KMC/ATX bolts a visual inspection every oil change and that's about it. Whenever I've had to change my tires, all my bolts have come out without any issues. On average, I will have about 2 inserts total back out enough to require reinstallation. If I lived where salt and corrosion were an issue, I probably would give them a look after every winter.

Yeah, I have no experience with other beadlocks to know what size they use, but if torquing a bolt to 20/30 ft lbs puts the bolt under so much stress it breaks which leads to a cascade failure of adjacent components it sounds like the design could use some 'optimization' haha.

I'm pretty sure this is why Clifton bump up everything when he came out with the original Spyderloc wheels. As well all know, these eventually became the Slabs and pretty much all the new ATX/KMC wheels have the same design features.

Are the torque specs on the bolts the same between ATX and Trail Ready?

Trail Ready states 20 ft. lbs. ATX/KMC state 20-24 ft. lbs.

13_gecko_rubi

Caught the Bug

No it's less because smaller bolts. 18-20 is what all my non atx/kmcs have been. If you've owned both you would know how much bigger the bolts are and how much thicker the rings are.Are the torque specs on the bolts the same between ATX and Trail Ready?

I've never had issue with any (Trail ready, method, vision x, or kmc) but there is a difference for sure.

Sent from my SM-G930V using WAYALIFE mobile app

13_gecko_rubi

Caught the Bug

I usually inspect mine after 24 hours like Eddie said then after a couple hundred miles then never touch them again.So what’s a good inspection schedule. I live where it doesn’t snow so no salt on the roads. I understand that you check torque periodically, but how often do you back out the bolts and check for corrosion? Do you replace all the bolts when you get new tires? I’m curious as I’m considering beadlocks on my build, and want to understand the best practices to use. I don’t mind extra maintenance or service, just want a clear picture. Thanks!

Yes u replace the bolts any time you take the rings off. Except kmc says u can re-use theirs I believe. I have never changed tires on a set of kmcs so have never reused them but I think they say u can. If i remember right they use 3/8 vs 5/16 on all others.

Sent from my SM-G930V using WAYALIFE mobile app

I usually inspect mine after 24 hours like Eddie said then after a couple hundred miles then never touch them again.

Yes u replace the bolts any time you take the rings off. Except kmc says u can re-use theirs I believe. I have never changed tires on a set of kmcs so have never reused them but I think they say u can. If i remember right they use 3/8 vs 5/16 on all others.

Sent from my SM-G930V using WAYALIFE mobile app

Do the models running smaller bolts run #10 or #8 bolts? Slightly bored at work haha.

Yup, what 13_gecko_rubi said. Most beadlock wheels come with smaller 5/16 grade 8 bolts. ATX/KMC run bigger 3/8" bolts. Also, you will see that most beadlock wheels have very thin rings. ATX/KMC have rings that are easily 2 times thicker.

SDG

Caught the Bug

Thx for the info guys. For some reason in was thinking the ATX/KMC was 1/4 which is why I was guessing at the 8 or 10 for the others. Been a while since I looked at them haha.

Was just wanting to take a look at the loads the diff size bolts can take. The more I look at it the more complex it is haha.

Was just wanting to take a look at the loads the diff size bolts can take. The more I look at it the more complex it is haha.

jesse3638

Hooked

I'm running Raceline Monsters. As mentioned they are I believe 5/16 grade 8. There are 32 per wheel and had the thicker aluminum ring been available that's what I'd have gone with. Don't the ATX wheels have 24 bolts?

Sent from my 2PYB2 using WAYALIFE mobile app

Sent from my 2PYB2 using WAYALIFE mobile app

fiend

Caught the Bug

I'm running Raceline Monsters. As mentioned they are I believe 5/16 grade 8. There are 32 per wheel and had the thicker aluminum ring been available that's what I'd have gone with. Don't the ATX wheels have 24 bolts?

Sent from my 2PYB2 using WAYALIFE mobile app

Yes, 24 bolts. On Chamber Pro IIs, anyway.

jesse3638

Hooked

Wonder if 32 5/16" bolts offer the same strength as 24 3/8" bolts.Yes, 24 bolts. On Chamber Pro IIs, anyway.

Sent from my 2PYB2 using WAYALIFE mobile app

SDG

Caught the Bug

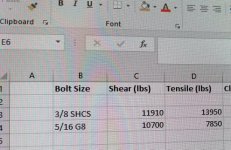

So from what I could find... here is a 3/8 socket head cap screw (which apparently only come in 1 grade, alloy) vs a grade 8 5/16 bolt... the shear on both is about the same, while the tensile on the 3/8 is almost 2x that of the 5/16.Yup, what 13_gecko_rubi said. Most beadlock wheels come with smaller 5/16 grade 8 bolts. ATX/KMC run bigger 3/8" bolts. Also, you will see that most beadlock wheels have very thin rings. ATX/KMC have rings that are easily 2 times thicker.

So if the load is in the tensile direction the 3/8 design is stronger, if it's in the shear, then the 5/16 grade 8 is stronger. I assume it is a mix of the two but not a clue what the % contribution from each would be.

While there are 33% more of the smaller bolts, they are only half as strong with respect the tensile strength.

One observation is that because there are more bolts in the smaller bolt design, and they are not to be reused, they must be getting near their yield strength where they are worried about stretch etc.

Slow day at work today!

dillard09

New member

When I got my replacements I called and spoke with AJ over at Spyderlock. She knows her stuff. I got inserts, bolts, and an insert tool from her. Still have a few inserts and bolts left.So for us ATX guys (chamber pro IIs), where do we come done re bolt replacement? I’ll be getting new tires soon ... The 3/8” bolts look pretty stout to me, and I’m in SoCal so don’t have corrosion issues. That’s said, I’d obviously like to avoid catastrophic failures.

1

Sent from my SAMSUNG-SM-G935A using WAYALIFE mobile app

Ddays

Hooked

When I got my replacements I called and spoke with AJ over at Spyderlock. She knows her stuff. I got inserts, bolts, and an insert tool from her. Still have a few inserts and bolts left.

1

Sent from my SAMSUNG-SM-G935A using WAYALIFE mobile app

So is Spyderlock recommending replacing the bolts AND inserts at a tire change?

So for us ATX guys (chamber pro IIs), where do we come done re bolt replacement? I’ll be getting new tires soon ... The 3/8” bolts look pretty stout to me, and I’m in SoCal so don’t have corrosion issues. That’s said, I’d obviously like to avoid catastrophic failures.

All I can say is that I started running Spyderlocs soon after they came out, way back when Clifton still owned the company. I have since run multiple sets of Slabs, Chamber Pro II's and now XD231's. ALL of these beadlock wheels have the same ring design and run the same bolts. During this time, I have run multiple sets of tires including Toyo, Nitto, Goodyear and Cooper and in different sizes and using the same bolts. Again, I've had to replace an insert here and there but that's about it. I do take special care to clean and inspect all my bolts prior to reinstalling but so far, I've not had an issue. This is not to say what I'm doing is right or even a good idea - just sharing what limited experience I have.

fiend

Caught the Bug

All I can say is that I started running Spyderlocs soon after they came out, way back when Clifton still owned the company. I have since run multiple sets of Slabs, Chamber Pro II's and now XD231's. ALL of these beadlock wheels have the same ring design and run the same bolts. During this time, I have run multiple sets of tires including Toyo, Nitto, Goodyear and Cooper and in different sizes and using the same bolts. Again, I've had to replace an insert here and there but that's about it. I do take special care to clean and inspect all my bolts prior to reinstalling but so far, I've not had an issue. This is not to say what I'm doing is right or even a good idea - just sharing what limited experience I have.

Thanks. When the time comes for new tires, I’ll chance it with the old bolts. Or, rather, let the guys at the install shop chance it.

dillard09

New member

No I ordered 20 bolts and inserts when I swapped tires last time just to be prepared. I had a couple bolts that came out with the insert. So instead of trying to get the bolt and insert apart I just replaced with new bolt and insert. I also inspected the inserts and bolts and changed the ones I felt needed. I think it was a total of 6 or 7 inserts and like 10-12 bolts on the 5 tires.So is Spyderlock recommending replacing the bolts AND inserts at a tire change?

Sent from my SAMSUNG-SM-G935A using WAYALIFE mobile app

13_gecko_rubi

Caught the Bug

So from what I could find... here is a 3/8 socket head cap screw (which apparently only come in 1 grade, alloy) vs a grade 8 5/16 bolt... the shear on both is about the same, while the tensile on the 3/8 is almost 2x that of the 5/16.

So if the load is in the tensile direction the 3/8 design is stronger, if it's in the shear, then the 5/16 grade 8 is stronger. I assume it is a mix of the two but not a clue what the % contribution from each would be.

View attachment 296119

While there are 33% more of the smaller bolts, they are only half as strong with respect the tensile strength.

One observation is that because there are more bolts in the smaller bolt design, and they are not to be reused, they must be getting near their yield strength where they are worried about stretch etc.

Slow day at work today!

Holding the tire on is all tensile. Now when u r grinding the wheel against a rock I could see some shear loads.

Sent from my iPad using WAYALIFE mobile app