You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

68' M715 AKA "Smokey", 8.1 engine on links, coils and 40's

- Thread starter Rock40

- Start date

Rock40

Active Member

Thanks! I’ve got plenty of time to work on it now that the season has changed, hopefully I’ll be able to make some very steady progressSo glad to see this back underway!

wjtstudios

Hooked

So clean, amazing skills

Bullwinckle

Hooked

Damn that looks good! Great metal work.

Rock40

Active Member

So clean, amazing skills

Damn that looks good! Great metal work.

Thanks Gents! It's slow and steady for sure. Lots more sheet metal massaging to go

FFPulley77

Hooked

incredible work!

Rock40

Active Member

Thanks! Yeah those flight suits are great, but this one is just about done in at this pointLooking forward to seeing it finished up...Project is looking good. Love the flight suit.

incredible work!

Rock40

Active Member

Well, unfortunately no. If the entire truck had looked like the engine bay area/inner fenders, I would have left it and enjoyed the patina but.....It had 3-4 coats of terrible brush paint all over it. Including a horrific orange. So, eventually it'll all get media blasted, primed and re-painted with a Rapco military paintAmazing! Are you going to try to make the new fender area look old?

Cousin Clyde

Hooked

Jesus dude. This build is just hammering the incredible meter. Inspires me to get creative.

wjtstudios

Hooked

Going to another level! Awesome

wjtstudios

Hooked

Nice and clean

Rock40

Active Member

Finished out the rest of the USB plugs today

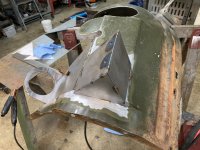

Also, this M715 never had grill of any sort, just a great gaping hole open to the radiator. Maybe the grill was lost years ago, who knows Wanting to avoid jamming a stick right through a very expensive radiator, I picked up some 316 stainless expanded metal. Then, I replaced the 5 factory sheet metal tabs with much heavier 1/8” units

Wanting to avoid jamming a stick right through a very expensive radiator, I picked up some 316 stainless expanded metal. Then, I replaced the 5 factory sheet metal tabs with much heavier 1/8” units

Formed the expanded metal a bit with a sanding wheel, TIG welded some stainless 3/8-16 nuts on the backside and…

Also, this M715 never had grill of any sort, just a great gaping hole open to the radiator. Maybe the grill was lost years ago, who knows

Formed the expanded metal a bit with a sanding wheel, TIG welded some stainless 3/8-16 nuts on the backside and…

Last edited: