You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VIDEO - JL JOURNAL : A BAD VIBE - Tracking Down & Fixing Driveshaft Vibrations

- Thread starter wayoflife

- Start date

F

Fionayeti

Guest

I'm far from offended.

As far as SoCal libtards, not sure who you're referring to, but if it's Overlander, he's probably the furthest thing away from a libtard on that political spectrum.

Good, then perhaps I could get along with Overlander...even with his potty mouth. If he's so far right then what's he doing in Calistupid then? Either way, the shafts were fine when installed and then all of a sudden they're not. So why? And why didn't Adam's fix the problem?

So let me start off saying I’m a big fan! I enjoy your videos, especially the travel ones where you explore trails and talk about the history of the areas you visit. And I always learn alot from you and the people on this forum. So please take what I’m about to say as curiosity, not criticism.

So, let me start off by saying, I don't have a clue as to who you are but for a guy who says he really enjoys our videos, I'm kinda surprised that you missed so many details that should have made things crystal clear.

In case of your driveshaft issue, I have some questions. I’m not here to defend Adam’s or any other maker, as it seems you’re not a big fan of branded shafts with cool stickers. I like to support my local vendors too and quite frankly, I’ve had more issues with local 4x4 driveline shops than the big brands.

In the case of your local driveline shop, I guess it sucks to be you. Of course, there's a reason why I never mentioned Adam's in this video and it's because I wasn't trying to throw them under the bus. Not like I wouldn't have a right to being that I am a PAYING CUSTOMER who paid more than double what it would have cost me to have a shaft made locally but, I digress.

If I follow your build sequences, it seems you had a short Evo lift, then a Rancho lift and then an even taller Rancho lift. Before the last lift, somewhere in there you put on the new Adam’s shafts and it sounded like you were happy. Do you think with all the lift changes, pinion and caster changes, not to mention the new front axle, all those things combined had an effect on the Adam’s shafts performance? It sounds like (obviously) the Adam’s shafts you bought weren’t sized properly for the new lift and axle changes. Is it then Adam’s fault the shafts were over-extended and not performing well because of the change in lifts, axle, pinion and caster?

Apparently, you haven't been following very carefully. If you had, you would have known that we installed our Adam's driveshafts AFTER installing our tall Rancho Lift and SPECIFICALLY because the factory driveshaft is too wide in diameter and was hitting our gas tank skid plate. The new shafts were to help mitigate this and we ultimately ended up installing a track bar relocation bracket as well to help things out even more. As I stated in this video, we had a vibration from day one but made the assumption that it might have been due to me having done something wrong. I went on to explain how I tried making adjustment after adjustment but could never get it right or at least, not until getting the rear shaft re-balanced. Also, since you seemed to have missed it in all our videos including this one, the front shaft will NOT spin unless you're in 4WD and this is because of the FAD. After installing our ProRock 44, we really started to hear and feel bad vibrations even after setting the pinion in line with the shaft. Of course, this is only something we could do being that the ProRock has so much built in caster. But, the vibration was still there and just as bad and as I clearly state in this video, I assumed that it might have been caused to the shaft being extended an inch too long. As in, I still wasn't blaming Adam's for anything other than charging me more than double what it would have cost to have shafts made locally and why the first thing I did to address my vibes was get my front shaft re-tubed. It was only until AFTER I removed the front shaft and went for a test drive with just the rear shaft that I realized I still had the same vibes as I had before and decided I just wanted them gone.

Did your local driveline shop confirm that the Adam’s shafts were not balanced properly? But if that’s true then how were they working well before the new lift? Are shafts balanced per lift height?

Adam's made my shafts based on the measurements they require and on the lift that I have installed right now. My local driveline shop took my Adam's rear shaft and made it so that it no longer vibrates. Everything on it is exactly the same except for the fact that it now has balancing weights on it. Up front, there was still plenty of splines to work with and a re-tube shouldn't have been necessary but I took it upon myself to have it made an inch longer and this as opposed to assuming the lack of balancing weights was the cause of my vibration.

Why didn’t you give Adam’s a call (Maybe you did) and tell them your problem and give them a chance to make a wrong a right? If you did call them, did they not want to help you fix the problem?

What you see in the video pretty much how things played out in real time. As in, I wasn't sure what the problem was or that balancing was in fact the issue until AFTER we got it fixed. What I knew was that I needed to get my front shaft re-tubed and doing that locally was cheap to do. The rear shaft is what really stung but I wasn't about to ship a very heavy shaft that measures over 48" to them, lose it for days on end and only to hope they'd make things right. Hell, I can assure you that I paid less to have it re-balanced locally than it would have cost me to ship it to them and again.

I doubt if you had an issue with your new Dynatrac axle you would have gone to your local axle shop and have them fix it and then say Dynatrac screwed up. You’d let Dynatrac or any of the other brands stuck to the side of your Jeep make the wrong a right. Which as respected brands, they should, especially when you support their products.

LOL!! Here we go.... :rolleyes2:

First off, I've NEVER had a problem with ANY of the 10 Dynatrac axles I've run over the years. Second, a ProRock 44 costs about $5000 and I don't know of too many local shops that specialize in making brand new custom axles or at least, on this level. Second, it only cost me $94 to have a $750 driveshaft re-balanced locally and within an hour. Call me crazy but I think I can just take care of that one myself.

As far as the other brands stuck to the side of my Jeep goes, I guess you mean like Tuffy and how I showed they didn't give me all the hardware I needed in my installation video of their security deck. Or maybe LoD and how I point out how my LED fog lights wouldn't install into their front bumper. Yeah, I would never be truthful about that kind of stuff, you know - because I have stickers of them on the side of my Jeep :rolleyes2:

I suppose now I‘ll get lots of forum backlash coming to your defense! Ha! Seriously, I’m just trying to understand. I trust your judgement and professionalism. I run some of the brands you support, because I see them work on your Jeep, therefore, I’m less skeptical, so I trust that they’ll work for my applications.

Your skepticism is a result of you not understanding things. Of course, this is because you already have it in your mind what you've chosen to believe, rather than spending more of your time paying closer attention to details that are provided.

WJCO

Meme King

Either way, the shafts were fine when installed and then all of a sudden they're not. So why? And why didn't Adam's fix the problem?

They weren't always fine. 8:23 in the video. The vibrations were always there.

I’ve had a bad rear driveline vibration before...it appeared that I knocked off a weight on the trail (Rubicon) and had to drive back to Seattle while trying to find the perfect speed that minimized the vibration...it sucked.

Thank you for the informative video...it had a good vibe...

Exactly why I always recommend that people find a local shop to work with. If you play with your Jeep as hard as you think you do, you'll need one if only to fix weights that you will knock off on the trail. :yup:

Good informative video, too me it kinda looks like it's easier to change a shaft on a jl compared to a jk, like easier access. But maybe not

Well, for sure the factory flange nuts are a hell of a lot easier to work with. Access to everything else is better too. :yup:

Yup I watched. Just wondering why Adam's didn't fix the problem.

Because I didn't know they were the cause of the problem until I found the cause. Besides, getting the shaft from them once was enough for me. :rolleyes2:

He changed pinion angle and caster a bunch so im pretty sure that means he was trying to dial in with his lift height. Plus, while I may be wrong, the 3.5 Rancho is the only lift he's ran with aftermarket driveshafts on Jet Li. On top of all that, knowing Eddie, I would assume be would go with what he knows and can get him going fast and correctly, rather than weeks off drawn out time for the manufacturer to hopefully get it right, it's one thing when you know and trust them to fix it..I also don't think he was so much griping about the cost to fix as much as the difference in original cost, just my thoughts though.

This ^^^^^

I got the driveshafts BECAUSE of the lift I installed. I've been working addressing the vibes since last October and trying everything except getting a re-balance. You know, because they were new shafts and it couldn't be the cause of them. And really, why would I ship a heavy shaft that measures over 48" to a shop that already gave me the shaft once and just to wait around for days on end to see if they could help me out. No, at this point and time, I figured another $94 and an hour out of my day would be fine especially knowing they would get it right.

notnalc68

That dude from Mississippi

Great video. Glad you got it sorted. I can’t figure why the guy thinks you were overtly bashing the drive shaft manufacturer, because I didn’t see you do any of that.

Sent from my iPhone using WAYALIFE mobile app

Sent from my iPhone using WAYALIFE mobile app

Also from the sounds of it, it appears that they didn't even know the driveshafts WERE the problem until they removed them, rebalanced them, and reinstalled them. It's not like you can visually look at it and say 'it's out of balance.'

This ^^^^ Hence, why I'd been working to address them for as long as I had.

Either way, the shafts were fine when installed and then all of a sudden they're not. So why? And why didn't Adam's fix the problem?

They weren't always fine. 8:23 in the video. The vibrations were always there.

Once again, this ^^^^^ Clearly, someone here is paying attention.

Great video. Glad you got it sorted. I can’t figure why the guy thinks you were overtly bashing the drive shaft manufacturer, because I didn’t see you do any of that.

Glad you enjoyed the video. As far as bashing goes, I don't even think I mentioned them once by name in this video. I really thought I was just sharing exactly how things played out.

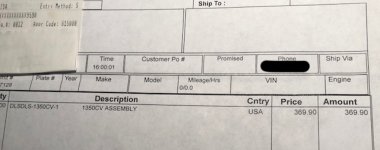

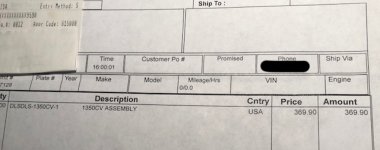

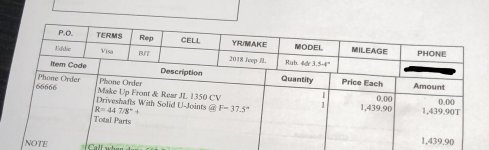

And since we're at it, here's a copy of my last invoice for the brand new 1350 driveshaft that I bought for Moby from my local shop. As you can see here, it just cost $369.90.

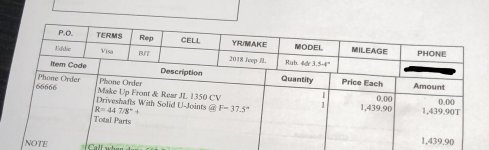

And, here's what Adam's charged me for two 1350 shafts.

Obviously, you'd have to divide that by two but that still gets you $719.95 each.

Crazy to think I would get grief for trying to save people some money or that I should somehow help protect a vendor that I BOUGHT parts from. :rolleyes2:

And, here's what Adam's charged me for two 1350 shafts.

Obviously, you'd have to divide that by two but that still gets you $719.95 each.

Crazy to think I would get grief for trying to save people some money or that I should somehow help protect a vendor that I BOUGHT parts from. :rolleyes2:

fiend

Caught the Bug

Nice video. Seems like Adams sent yours out without balancing. Doesn’t inspire confidence in their QC.

Unfortunately now when I drive my JK I’m going to be either feeling or imagining driveline vibrations. [emoji53]

Sent from my iPhone using WAYALIFE mobile app

Unfortunately now when I drive my JK I’m going to be either feeling or imagining driveline vibrations. [emoji53]

Sent from my iPhone using WAYALIFE mobile app

OverlanderJK

Resident Smartass

Yup I watched. Just wondering why Adam's didn't fix the problem. Sorry to offend that SoCal libtard and yourself. I don't think calling people F-ing idiots is helpful. Just trying to understand.

Adams didn’t fix the problem cause he didn’t ask jackass. Can you understand fuck off?

Sent from my iPhone using WAYALIFE mobile app

F

Fionayeti

Guest

So, let me start off by saying, I don't have a clue as to who you are but for a guy who says he really enjoys our videos, I'm kinda surprised that you missed so many details that should have made things crystal clear.

In the case of your local driveline shop, I guess it sucks to be you. Of course, there's a reason why I never mentioned Adam's in this video and it's because I wasn't trying to throw them under the bus. Not like I wouldn't have a right to being that I am a PAYING CUSTOMER who paid more than double what it would have cost me to have a shaft made locally but, I digress.

Apparently, you haven't been following very carefully. If you had, you would have known that we installed our Adam's driveshafts AFTER installing our tall Rancho Lift and SPECIFICALLY because the factory driveshaft is too wide in diameter and was hitting our gas tank skid plate. The new shafts were to help mitigate this and we ultimately ended up installing a track bar relocation bracket as well to help things out even more. As I stated in this video, we had a vibration from day one but made the assumption that it might have been due to me having done something wrong. I went on to explain how I tried making adjustment after adjustment but could never get it right or at least, not until getting the rear shaft re-balanced. Also, since you seemed to have missed it in all our videos including this one, the front shaft will NOT spin unless you're in 4WD and this is because of the FAD. After installing our ProRock 44, we really started to hear and feel bad vibrations even after setting the pinion in line with the shaft. Of course, this is only something we could do being that the ProRock has so much built in caster. But, the vibration was still there and just as bad and as I clearly state in this video, I assumed that it might have been caused to the shaft being extended an inch too long. As in, I still wasn't blaming Adam's for anything other than charging me more than double what it would have cost to have shafts made locally and why the first thing I did to address my vibes was get my front shaft re-tubed. It was only until AFTER I removed the front shaft and went for a test drive with just the rear shaft that I realized I still had the same vibes as I had before and decided I just wanted them gone.

Adam's made my shafts based on the measurements they require and on the lift that I have installed right now. My local driveline shop took my Adam's rear shaft and made it so that it no longer vibrates. Everything on it is exactly the same except for the fact that it now has balancing weights on it. Up front, there was still plenty of splines to work with and a re-tube shouldn't have been necessary but I took it upon myself to have it made an inch longer and this as opposed to assuming the lack of balancing weights was the cause of my vibration.

What you see in the video pretty much how things played out in real time. As in, I wasn't sure what the problem was or that balancing was in fact the issue until AFTER we got it fixed. What I knew was that I needed to get my front shaft re-tubed and doing that locally was cheap to do. The rear shaft is what really stung but I wasn't about to ship a very heavy shaft that measures over 48" to them, lose it for days on end and only to hope they'd make things right. Hell, I can assure you that I paid less to have it re-balanced locally than it would have cost me to ship it to them and again.

LOL!! Here we go.... :rolleyes2:

First off, I've NEVER had a problem with ANY of the 10 Dynatrac axles I've run over the years. Second, a ProRock 44 costs about $5000 and I don't know of too many local shops that specialize in making brand new custom axles or at least, on this level. Second, it only cost me $94 to have a $750 driveshaft re-balanced locally and within an hour. Call me crazy but I think I can just take care of that one myself.

As far as the other brands stuck to the side of my Jeep goes, I guess you mean like Tuffy and how I showed they didn't give me all the hardware I needed in my installation video of their security deck. Or maybe LoD and how I point out how my LED fog lights wouldn't install into their front bumper. Yeah, I would never be truthful about that kind of stuff, you know - because I have stickers of them on the side of my Jeep :rolleyes2:

Your skepticism is a result of you not understanding things. Of course, this is because you already have it in your mind what you've chosen to believe, rather than spending more of your time paying closer attention to details that are provided.

I am a big fan! Just wanted to understand more about your driveshaft situation. I'd be pissed too if I paid full price and the shafts didn't perform! Real pissed! I get it! You didn't mention Adam's in the vibe video but in your install video you named them, so who else could it have been? I have no bias or preconceived notions when I wrote my questions in response - or how would I learn? What point would that make? Reread my post and you'd see my questions and points are sincere. I'm not that kind of person to bash and swear and put you down...what does that achieve? If I missed things you covered in your video or got timelines wrong then I take responsibility. No biggie.

This forum I thought is where Jeepers share knowledge, ask questions (sometimes stupid)! But no one deserves to be sworn at and made to be feel stupid or have eyes rolled at or told "Sucks to be you". What kind of forum is that? I wasn't even bashing the brands who align with you. I run Dynatracs - love them. They're Heavy, but I love them!

In the end, I want you to share what doesn't work and what does! That's why I come here to learn because you tell the truth. I suppose you get lots of people challenging you and bashing you so I get your mindset and skepticism on people's intentions, but that's not me. Okay, enough already. And I thought mountain patrol in Afghanistan was hard.

You host the best Jeep forum around. Thanks for listening.

F

Fionayeti

Guest

Adams didn’t fix the problem cause he didn’t ask jackass. Can you understand fuck off?

Sent from my iPhone using WAYALIFE mobile app

Hey Eddie, one of your bitches from the basement got unchained!

I am a big fan! Just wanted to understand more about your driveshaft situation. I'd be pissed too if I paid full price and the shafts didn't perform! Real pissed!

It's funny because I don't think I ever once said I was "pissed" about anything. Sure, I expressed disappointment but more in myself than anything. I knew better.

I get it! You didn't mention Adam's in the vibe video but in your install video you named them, so who else could it have been?

Fact of the matter is, it really shouldn't matter who it was. It could have been Tom Woods for all I care. My point was to keep things positive, to promote the idea of using a local shop and for the reasons I stated.

I have no bias or preconceived notions when I wrote my questions in response - or how would I learn? What point would that make? Reread my post and you'd see my questions and points are sincere. I'm not that kind of person to bash and swear and put you down...what does that achieve? If I missed things you covered in your video or got timelines wrong then I take responsibility. No biggie.

If you say so.

This forum I thought is where Jeepers share knowledge, ask questions (sometimes stupid)! But no one deserves to be sworn at and made to be feel stupid or have eyes rolled at or told "Sucks to be you". What kind of forum is that? I wasn't even bashing the brands who align with you. I run Dynatracs - love them. They're Heavy, but I love them!

The "sucks to be you" was an honest statement regarding the fact that you said you have no good local driveline shop you can work with. If I were in your shoes, it would suck just as much for me. As far as "bashing" brands go, I couldn't care less if you did - it'd be YOUR OPINION and YOUR RIGHT to do so.

In the end, I want you to share what doesn't work and what does! That's why I come here to learn because you tell the truth. I suppose you get lots of people challenging you and bashing you so I get your mindset and skepticism on people's intentions, but that's not me. Okay, enough already. And I thought mountain patrol in Afghanistan was hard.

You host the best Jeep forum around. Thanks for listening.

Funny, I'm pretty sure all I did was share my recent experiences. I pointed out the problem I had and how I was ultimately able to fix it. You asked questions based on your understanding of things and I simply responded to it.

Sharkey

Word Ninja

LOL!! Who knew that a simple video intended to HELP people by showing a problem I had and how I ultimately fixed it would get so many people's panties in a pinch. Here's one that got posted on YouTube from a Jeep Fanatic and to suggest that I was "slandering" Adam's with an "anti-propaganda" message. :rolleyes2:

WJCO

Meme King

LOL!! Who knew that a simple video intended to HELP people by showing a problem I had and how I ultimately fixed it would get so many people's panties in a pinch. Here's one that got posted on YouTube from a Jeep Fanatic and to suggest that I was "slandering" Adam's with an "anti-propaganda" message. :rolleyes2:

Wow. Dear Lord. Full moon for sure. All of these fuckers coming out of the woodwork. Wow, a simple 'Glad you got your Jeep fixed' seems like a more proper reply. What's wrong with all these people?

longarmwj

New member

So let me start off saying I’m a big fan! I enjoy your videos, especially the travel ones where you explore trails and talk about the history of the areas you visit. And I always learn alot from you and the people on this forum. So please take what I’m about to say as curiosity, not criticism.

In case of your driveshaft issue, I have some questions. I’m not here to defend Adam’s or any other maker, as it seems you’re not a big fan of branded shafts with cool stickers. I like to support my local vendors too and quite frankly, I’ve had more issues with local 4x4 driveline shops than the big brands.

If I follow your build sequences, it seems you had a short Evo lift, then a Rancho lift and then an even taller Rancho lift. Before the last lift, somewhere in there you put on the new Adam’s shafts and it sounded like you were happy. Do you think with all the lift changes, pinion and caster changes, not to mention the new front axle, all those things combined had an effect on the Adam’s shafts performance? It sounds like (obviously) the Adam’s shafts you bought weren’t sized properly for the new lift and axle changes. Is it then Adam’s fault the shafts were over-extended and not performing well because of the change in lifts, axle, pinion and caster? Did your local driveline shop confirm that the Adam’s shafts were not balanced properly? But if that’s true then how were they working well before the new lift? Are shafts balanced per lift height?

Why didn’t you give Adam’s a call (Maybe you did) and tell them your problem and give them a chance to make a wrong a right? If you did call them, did they not want to help you fix the problem? I doubt if you had an issue with your new Dynatrac axle you would have gone to your local axle shop and have them fix it and then say Dynatrac screwed up. You’d let Dynatrac or any of the other brands stuck to the side of your Jeep make the wrong a right. Which as respected brands, they should, especially when you support their products.

I suppose now I‘ll get lots of forum backlash coming to your defense! Ha! Seriously, I’m just trying to understand. I trust your judgement and professionalism. I run some of the brands you support, because I see them work on your Jeep, therefore, I’m less skeptical, so I trust that they’ll work for my applications.

Keep up the great work!

Your future driveline vibrations can be remedied by having him pull out and apply more KY. Thanks for stopping by.

Sent from my iPhone using WAYALIFE mobile app

Wow. Dear Lord. Full moon for sure. All of these fuckers coming out of the woodwork. Wow, a simple 'Glad you got your Jeep fixed' seems like a more proper reply. What's wrong with all these people?

LOL!! Kinda what I was thinking. Maybe it's just me but I really thought that an honest presentation like this would be appreciated. Instead, I'm accused of "slander" and "anti-propaganda". Hell, maybe I should just start asking for free shit and pimping it instead. :rolleyes2:

Your future driveline vibrations can be remedied by having him pull out and apply more KY. Thanks for stopping by.

:shock: :cheesy: