Thanks for the thorough explanation. Looking forward to seeing the full production kit and the rest of your pieces.

Bumpers and sliders look great! Welcome to Wayalife!

Looks great and the price is right!

Thanks for the interest and support everyone!

Your side steps say their rocker guards too? How does that work?

In my opinion, while there are different ways that protection can be added to the actual rocker panels on the JL Body, before heading down that road we should first pose the question of: what are we protecting the rocker panels from? In my opinion, in this case protection should be added to resist rocks strikes (either kicked up by the tires or protruding from the ground) and/or car door strikes (from vehicles parked next to you). By adding side steps (any manufacturer), unless you're being impacted by a door that can clear the side steps (e.g. lifted truck or suv), you're covered already on the door strikes to your rocker panels.

Rock strike and rock impact protection should be addressed by testing. In my opinion, there are two standards to beat for add-on rock impact production, the OE JL Rubicon rock rails (as the base standard) and then an underframe skid plate.

The OE JL Rubicon rock rails are body mounted. While the OE JL Rubicon rock rails should bear the weight of the vehicle (forklift test), they're actually not meant to be load bearing because they're body mounted. The "rock rails" description actually refers to deflecting rocks that are kicked up as opposed to "rock sliders" which are more of an underframe skid plate.

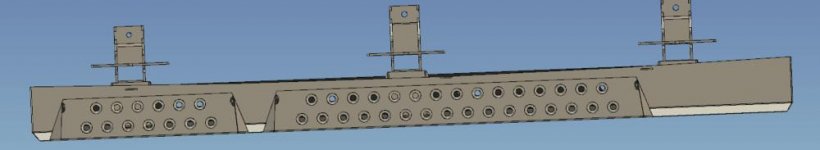

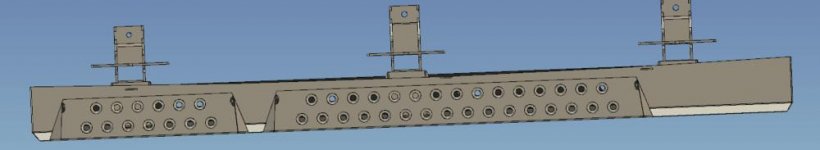

Our JL Side Armor Steps are constructed from mixed 7/32″ and 1/4" (high strength steel brackets) and mixed 1/8" and 5/32" high strength steel (topside outer surfaces) and are seam welded along the step plates. Any impact forces are dispersed and spread across all of the mounting points evenly as opposed to being concentrated in one area.

The primary issue with adding any sort of underframe skid plate meant to protect the frame rails themselves is that you will lose ground clearance where the skid plate is attached. While there are solutions on other vehicles where they're advertised as allowing you to drag your vehicle over rocks and debris, if anyone actually attempts something like that the odds of getting high centered are pretty high. To clarify, in our opinion, avoiding the rocks will be safer than dragging/sliding your Jeep over them. On our JL Side Armor Steps, the mounting brackets sit higher than the lowest part of the OE body mount brackets.

There are also the issues of maintenance, the ability to repair whatever its attached to, and then also if installation can be reversed (in the case that you've leased your JL as opposed to outright ownership). With most of the current rocker guards that attach to the rocker panels by means of either drilling a series of holes on the vehicle rocker panels or using adhesives, in my opinion, water ingress (at the holes drilled), water retention (in the gap between the rocker panel and the product attached to the rocker panels), how applied forces are absorbed/spread/dispersed (shear vs compression, e.g. on a sheet of metal attached to the rocker panel, how thick is the metal and if it dents is it just transferring the impact to the rocker in a localized area, dimple to dimple), and if a serious enough force was applied, can the underlying area be repaired.

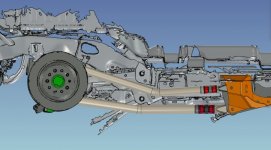

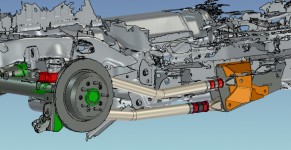

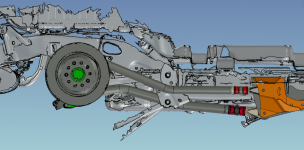

We've got both a body mounted version and a frame mounted version of our JL side steps: The ROAM JL Side Armor Steps which are body mounted and the ROAM JL Rock Sliders which are frame mounted. Our JL Side Armor Steps utilizes the same attachment points as the OE JL Rubicon rock rails. Our JL Rock Sliders utilizes preexisting bolt locations on the OE JL vehicle frame. Both our JL Side Armor Steps and our JL Rock Sliders do not require drilling or cutting or welding at all for installation and are designed to bear the weight of the vehicle (forklift test). Our JL Side Armor Steps are in production but we're still at least another few weeks out before our JL Rock Sliders will be committed to production. We're still testing our JL Rock Sliders to see if they're an improvement over our JL Side Armor Steps.

The Great Grape Ape said:

The ROAM slider are nice looking, and seem perfect as a step, but they likely won’t function the same for protection.

Most people don’t need or care for that level of protection and primarily need a functional step, that both looks the part and and has some of the added benefits not found on others (good platform with smaller gaps for dogs or high heels, good stone chip protection, etc), for most the ROAMs will be perfect

The Great Grape Ape said:

However, that difference in price is also likely due to that difference in build priorities.

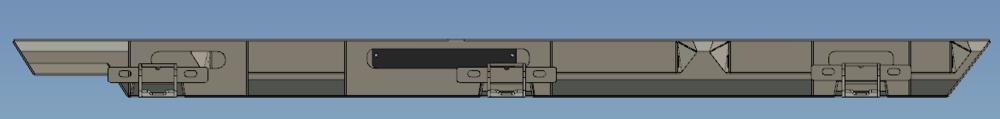

What sets our design, build process, and quality apart isn't just how strong our JL Side Armor Steps are, but rather how they're designed and built. They're not just straight square tubes, but profiled and precision laser cut on the interior edge to evenly and consistently follow the curvature of the vehicle. While they're built to carry the weight of the vehicle (forklift test), in my opinion, the forklift test should not be the defining benchmark for strength because the OE JL Rubicon Rock Rails will also carry the weight of the vehicle during the forklift test. Our side steps feature heavy duty 7/32" high strength steel brackets and mixed 1/8" and 5/32" high strength steel superstructure construction (topside outer surfaces). I've attached an image below showing the inside profile of our JL Side Armor Steps.

I spoke with you via email so soon as you get the 8” kit I will be able to give some reviews. Unfortunately there isn’t a lot of rock here in Louisiana so my rig will Be more geared for mud. I currently have a set of 42” Fury Mt’s ordered right now. It will get abused , but in a different way than most people on here use there rigs.

Thanks for the interest and support!

We're still a few weeks out from releasing our 6" and 8" JL Long Arm suspension systems. We have a policy of testing everything on our own development and demo vehicles so what our customers receive will be perfect. We're still in the process of sorting through how much actual suspension travel we can get out of a set of coilovers that a 3rd party is currently co-developing with us. The design specifications call for: lets say if we were adding 4 inches of lift to a vehicle then we also need to add at least 4" of suspension travel so you're not losing negative suspension travel and articulation.

Stay tuned for updates!

Welcome Roam! I dig the white letters. You can send me some of those slider/steps. I’ll give you a review.

Thanks for support!

When we're caught back up on production lets talk