Sorry for the delay. I won't be able to post much by way of pictures, as my wife and I are on the road headed wheeling for 3 days and won't be home until Monday. I've been working on the Jeep every night after work, and haven't been online much.

The rest of the install was pretty straightforward with some things listed below.

1. Front wheel speed sensors. I had a heck of a time getting the Jeep to recognize these until I called Dynatrac and they sent me a pdf for how to adjust them. Basically you put a 0.020" feeler gauge between the wheel speed sensor and you leverage it out against the feeler gage with a slotted screwdriver while tightening the adjustment socket head screw. If I can figure out how to post the pdf and it's kosher to post a Dynatrac pdf here I will, but a pm or call to Dynatrac will get it sent to your e-mail address. I can also send it if you pm me an address, keep in mind I'm on the road.

2. Rear E-brake lines. - There's a great writeup here:

https://wayalife.com/showthread.php?41495-Prorock-60-ebrake-cable-help/page2

Start with Eddie's post with photos on page 2. Also, Dynatrac will send you a pdf if you pm them here, or call them. I can also email, same as #1. It has a little more info and pictures. The 2 combined make it easy to figure out.

Why Dynatrac doesn't include a copy of #1 and #2 pdfs in the crate, or in an e-mail when you order is beyond me.

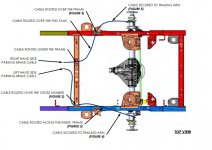

3. Front lower control arm pockets. I have no idea why they made them like this, but they hit the Jhonny Joints on my EVO FLCAs and limit full droop. I ground out a moon like section with an angle grinder, and now I'm back to being limited by shock travel just before the driveshaft touches the exhaust cross member. After looking it over, it turns out I did the same thing a couple of years ago on my PR44 and don't even remember doing so. I have ~9.5" of travel in the front with 4" plush rides and 37s. Down travel is limited by the shocks, but I have a paper's thickness of clearance between the 1350 and my exhaust crossover, and the uptravel is limited by my frame side trackbar mount.

4. Evo 60 Rockstars - I had to elongate the RLCA hole in the Rockstar with a carbide burr to line up with the hole in the Dynatrac bracketry when the Rockstar sits flush against the face. It was a pretty significant elongation, but the Dynatrac bracket is still doing all the RLCA mounting. Also, only the upper 5/16" bolt for the Rockstar would mount in Dynatrac bracket material. I had to drill a new hole in both the Rockstar and Dynatrac bracket for the lower one as there's a large pocket machined in the Dynatrac RLCA mount. Best bang for the buck upgrade I did imo, and easier to do before destroying the brackets on the trail.

Some other notes, not really issues:

I'm running 8 degrees of caster up front for now. The only reliable way I could find to measure it on the front PR60 is off the top of the top balljoint stud. Every other surface gave me an inconsistent measurement. The pinion seal face with a flat bar and angle finder worked well front and rear as well.

Rear driveshaft angle. I was able to set the rear axle pinion pointed directly at my xfer case so that the 1350 shaft I used has a 0 degree change at the pinion end. It's just under the maximum angle Dynatrac specified on the hang tag they provided. Measurements are taken with 4" plush rides, GTG there!

I lost 1/8" clearance at the pumpkin in the front from a PR44 to a PR60, which is AMAZING!

I lost 5/8" clearance at the pumpkin in the rear from a Dana44 to a Pro60, way better than I imagined!

Hutchinson Rock Monsters in 5x5.5 fit over the hubs just fine, and won't rub full lock to lock with 9.5" of suspension travel on 4" of lift with 37s at any point in the suspension position. I ordered these axles in 5x5.5 as a bunch of the wheel choices my wife and I like come in that pattern with less backspace. It was honestly aesthetics driven.

EVO extended rear brake lines seem significantly longer than I need with 9.5" of rear travel.

With 37s on 4" Plush rides, 3" of bump seems most appropriate in the rear. Cycling it seems JUST short of fully stuffing a tire. I had a 1" gap with 4" of bump.

If you're doing EVO King Air bumps in the front like I did, you'll need to come up with a way to mount the bump extensions. The Dynatrac pad is designed to take a single 1/2"-13 bolt in the center. The King's come with 2 smaller bolts. You can either drill and tap the pad, or pick up some hockey puck style extensions and get a socket head bolt. Fastenal had the bolts in varied sizes with a nice black coating in stock. You'll also need to drill out the bumpstop extension to 1/2" and countersink it if you buy a pre-made one. They all seem to have 3/8" holes....

You need a regular stock, not RHD flipped draglink. I didn't think about or realize this until the axles arrived.

We put 1.5 hours test on them mid-week in town, and 6 hours today. I have 3 more hours tomorrow of highway, and 3 days of wheeling before 9 hours home. I'll post back how they did. On the highway, with 37s, 5.13 is 2900 RPM with the cruise set. In the mountains the auto is constantly shifting down to 4 and giving me about 3400 rpm until you hit level ground or push it back into 5th gear. Driving great so far!

That's a really long post, and all for now.