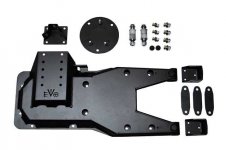

Two issues I see with the EVO design (and most other body mount carriers - and some frame mount carriers):

1. No matter how tight you make the bolt holding the tire/wheel bracket, it will still eventually slip in the slot (friction is not enough to overcome the effects of off-road and on-road vibration). Maybe consider a series of overlapping drilled holes with enough material protruding into the "slot" to provide a positive stop at multiple locations.

2. The most rattle/vibration-free compressive material in the system is the tire itself. With most of the body-mount tire carriers, whatever support there is within the carrier is on the hinge side of the carrier, requiring a separate compressible stop on the trailgate to support the driver-side of the tire/wheel. May consider extending the carrier far enough on the driver side so the tire can compress against it.

With this configuration, you locate the bolt holding the tire/wheel bracket in one of the holes that will only allow the lug nuts to be finger tightened such that the wheel is within approximately 1/2" of the bracket mounting surface. With both sides of the tire contacting the tire carrier, you tighten the lugs until they snug the wheel to the mounting surface (the tire is compressed about 1/2" against the spare tire carrier). In this scenario, the relationship between the tire/wheel and carrier doesn't change as the tailgate opens and closes (as it must with a door mounted stop since the hinge points of the carrier and door are different).