You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mission Control... We Have a Problem

- Thread starter wayoflife

- Start date

Not gonna lie, I got real lucky with this one and I almost missed it. I was just brushing off some of the dust as I was looking at things and just per chance saw it.That's a huge bummer but you got a damn good eye. If you do get it welded are you going to try and reinforce it with a truss?

IF we can get it welded, we may consider a truss to help support it. Although, Cindy is already leaning toward just getting a new axle - just to be safe. A lot to think about.

Nah, no heater and it's been stupid cold. I mean, I do have a torpedo heater but it's really loud and stinks. For now, I just suit up with some bibs and layer up and suffer a bit.Haha yea it’s a cold one for sure! I hope you have a heater in there at least to cut down a little of the bite.

Honestly, I was gonna reach out to you and see when we could get the ball rolling with the LT4 but then, thought that I should give everything a close once over first. So glad that I did.Oof, thats crazy! Definetly good you caught now and not doing 60+ MPH offroad with the LT4..

TrailHunter

Hooked

It’s always something… cool you caught it though. I just hope you can find another Jeep to wheel in the meantime.

yeah... I'll have to see what I can doIt’s always something… cool you caught it though. I just hope you can find another Jeep to wheel in the meantime.

Mike Pierson

Hooked

Wow, good eye spotting that! And yeah, glad you found it on the lift and not the whoops!

who me?? nah!!Damn...I think a new axle eventually...do you know anyone in the biz?...

hehe

Yeah, got real lucky with this one. I have visions of really bad things if I hadn't caught it.Wow, good eye spotting that! And yeah, glad you found it on the lift and not the whoops!

CalSgt

Hooked

Anyway, now the question is - what to do with this thing?

Demand Spicer take it back since it is in otherwise new uninstalled condition, then nut up if they won't cover the return shipping too.

Shit that's a tough one... But seriously I'd probably call Spicer to see if they're interested in helping you out, I mean it couldn't hurt to ask.

I'd consider a truss as part of my repair strategy too, I've never had one but assume this is what they're for.

ETA: just noticed you already said a truss is part of the plan

Slaphitter

Caught the Bug

As you can see, that's allowing the shaft to flop all over the place.

I thought this was a family forum.

AZVAJKU

Hooked

As some of you may know, Cindy and I have made some substantial changes to our 2020 Jeep JT Gladiator and the biggest of them, are the badass trailing arms by EVO. They literally allow us to do things that we really shouldn't be doing in a production vehicle and it really is amazing. But, being that we've put a lot of hard miles on it before the upgrade and after hammering on it right after the build, I decided that I really needed to take some time and give it a thorough once over. With that said...

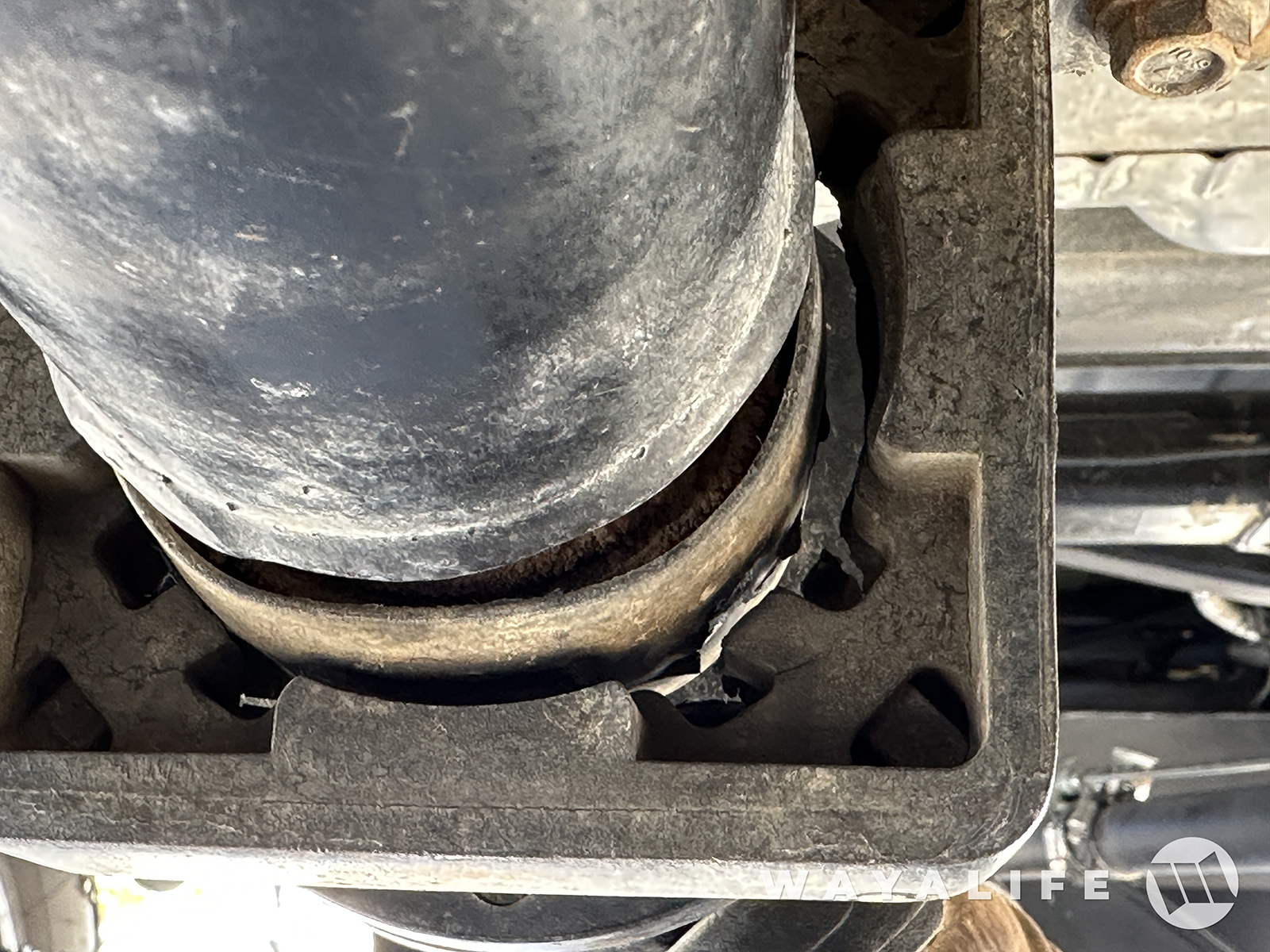

The first thing I found that needed some help was this - a blown out center support bearing or carrier bearing.

As you can see, the bearing has completely torn away from the rubber bushing and that's allowing the shaft to flop all over the place.

Fortunately, that's an easy enough fix and so I've already removed it and shipped it to JE Reel to have it replaced and have the whole shaft rebuild and rebalanced just for good measure.

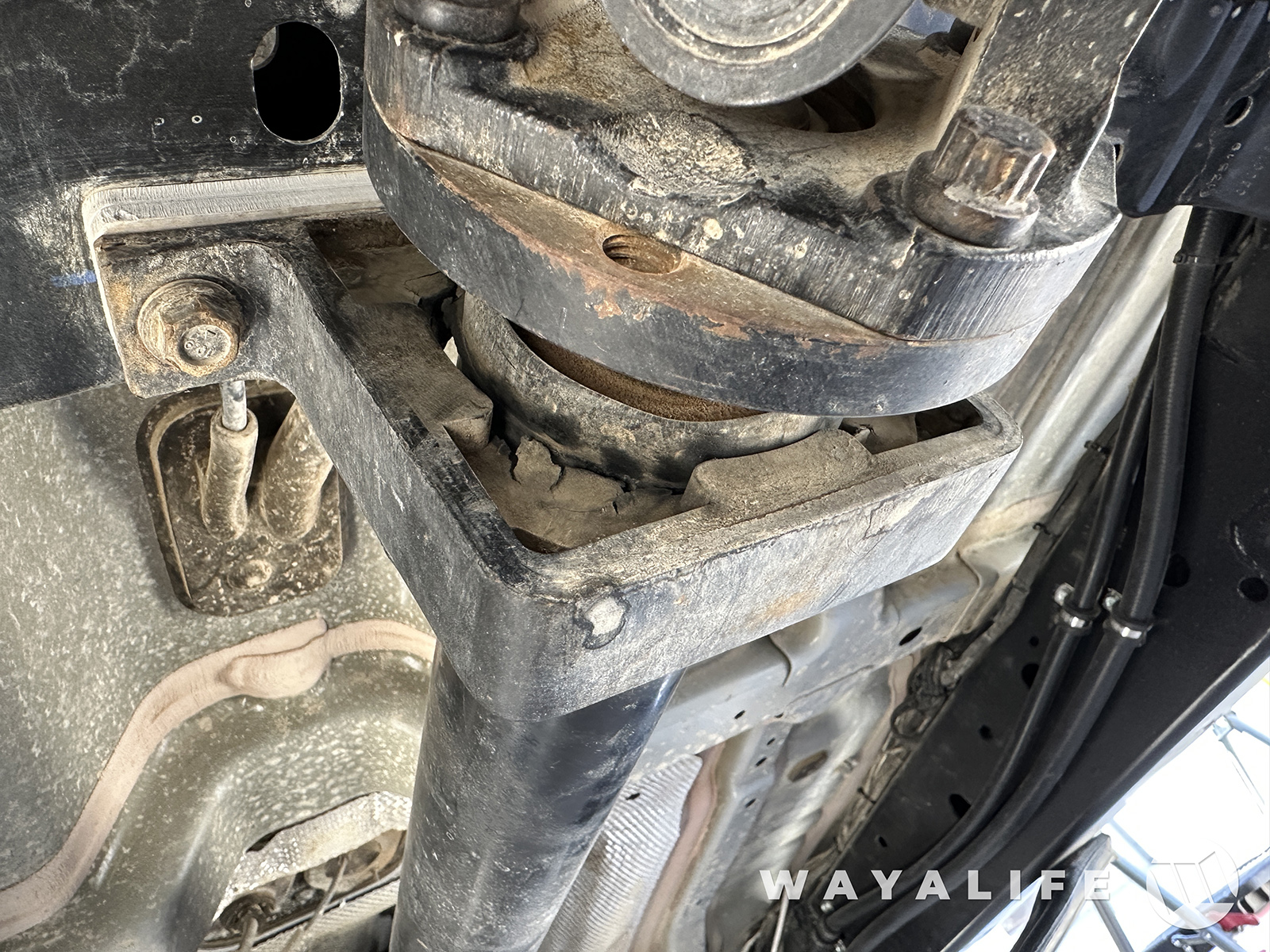

Now, the second problem is a bit more concerning. With 22" of vertical travel, the rear end of our Gladiator can now tear across serious whoops, at crazy speeds and without ever bottoming out. However, up front... that's a different story. As well as it has done and still does, there are times where the 12" of vertical travel just can't keep up with the rear and there have been a few... harder than I would prefer hits to it during our testing. And, after going over the front axle with a fine tooth comb, this is what I found.

Need a closer look?

Yup, that's a crack you're seeing and right on the webbing of the passenger side differential. It's about 1/2" long and while it's not leaking, it is clearly a point of failure and one that will need to be addressed before it becomes a bigger problem.

Crazy thing is, this is on a Dana UD60, a very stout axle and one that has held up to everything we've been able to throw at it or at least, up until now. And, this really goes to remind me that way more than playing on the rocks, SPEED can and will break anything and everything.

Anyway, now the question is - what to do with this thing?

Wasn’t Dana Spicer talking about a UD80? I think you had a picture of one at SEMA.

LOL - too funny.Demand Spicer take it back since it is in otherwise new uninstalled condition, then nut up if they won't cover the return shipping too.

Shit that's a tough one... But seriously I'd probably call Spicer to see if they're interested in helping you out, I mean it couldn't hurt to ask.

I'd consider a truss as part of my repair strategy too, I've never had one but assume this is what they're for.

ETA: just noticed you already said a truss is part of the plan

And yes, if a replacement axle is the only path forward, I may reach out to Spicer to see if they can help.

So far as I can tell, the crack is just on the webbing but yeah, if it's gone beyond that, nothing short of a new axle will probably fix the problem.To weld cast the crack needs to be cut out then filled back in right? If so hope that crack isn’t to far into the housing that it could cause an issue

LOL - yeah, it was supposed to be out already. In fact, a couple of years ago. There's just so much demand for their tier 1 products that their aftermarket products always end up on the back burner.Wasn’t Dana Spicer talking about a UD80? I think you had a picture of one at SEMA.

OverlanderJK

Resident Smartass

Would an 80 even be beneficial in the front due to the size and the limited travel as is?LOL - yeah, it was supposed to be out already. In fact, a couple of years ago. There's just so much demand for their tier 1 products that their aftermarket products always end up on the back burner.

I don't think so and I'm pretty sure it was only going to be made for the rear.Would an 80 even be beneficial in the front due to the size and the limited travel as is?

OverlanderJK

Resident Smartass

That’s what I thought too. This is the front correct? I thought I saw a tie rod in there but everyone kept saying 80 so made me second guess myself.I don't think so and I'm pretty sure it was only going to be made for the rear.

Also isn’t the 80 the same cast housing just slightly bigger? It’s not necessarily stronger at the pumpkin right?