greenMarine

Member

Like my other build this is going to go from zero to 100mph as I started this build in the spring of 2014 but just joined WOL.

I picked this 1980 - CJ-7 up in April of 2014. My original plan was to increase its value by addressing its issues and flipping it for a quick profit.

When I began getting into it I realized that the frame was busted along the rear cross member and as I began removing suspension bolts, steering bolts, and other bolts inside the frame they would break off, free spin.

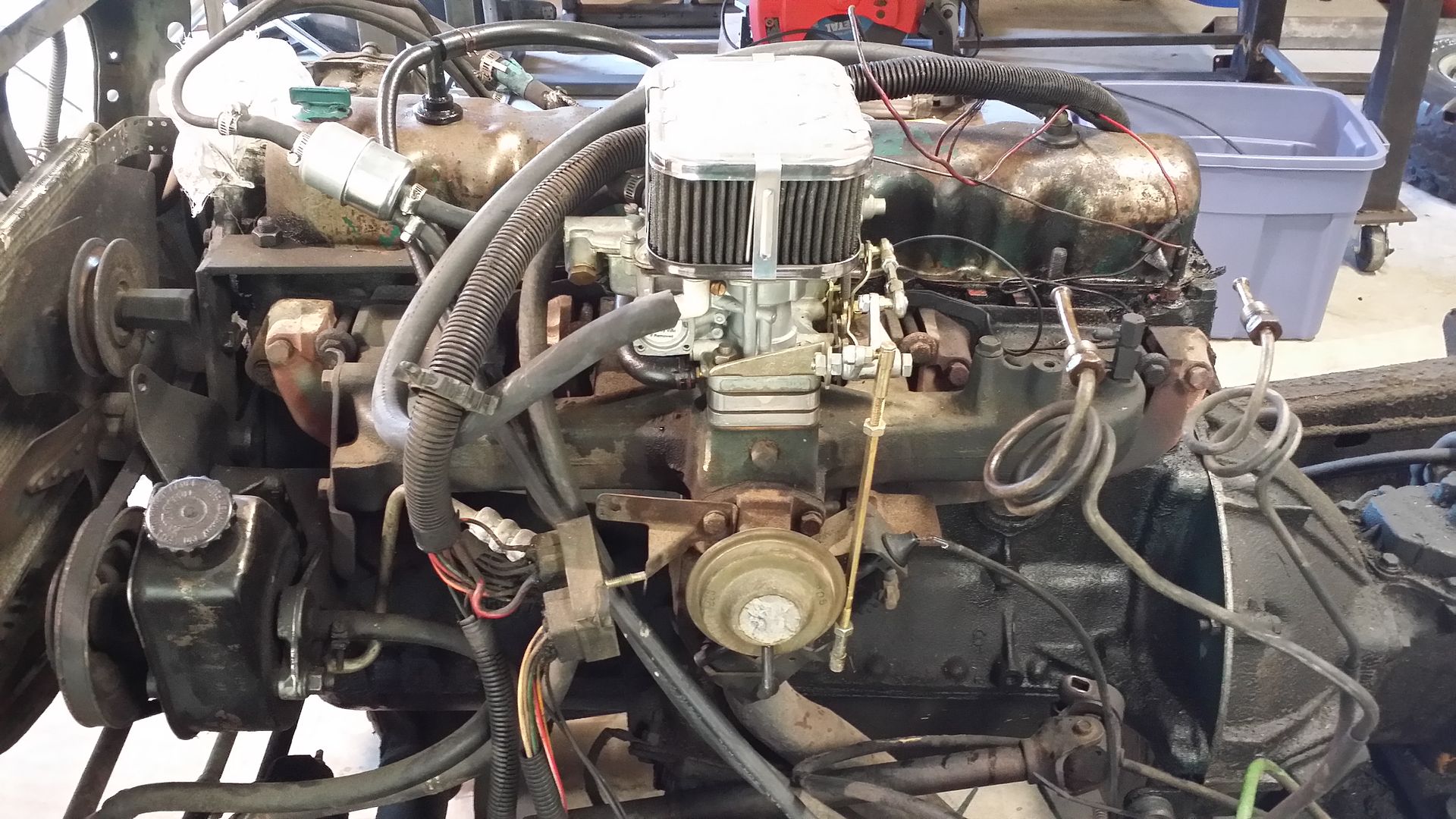

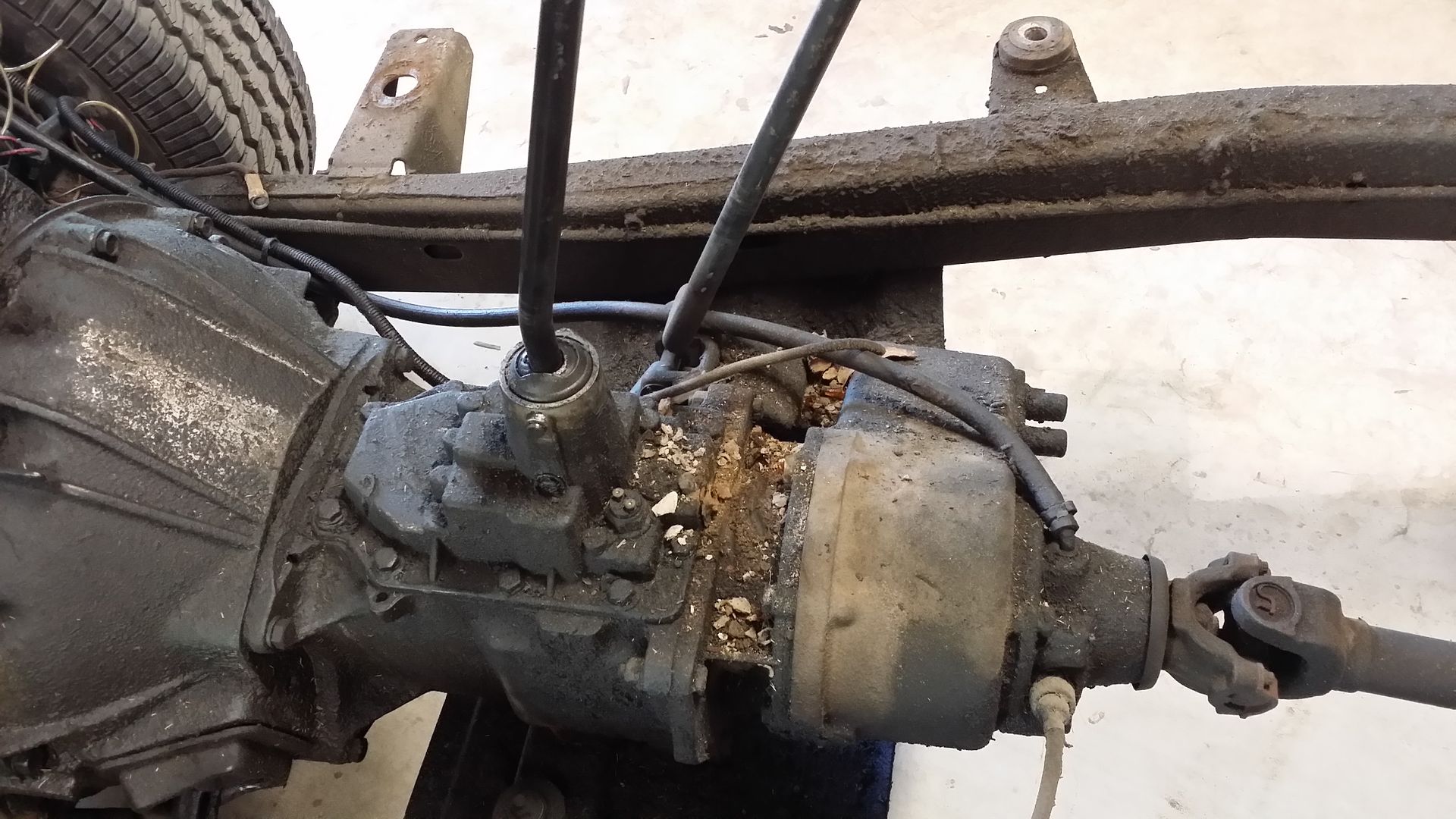

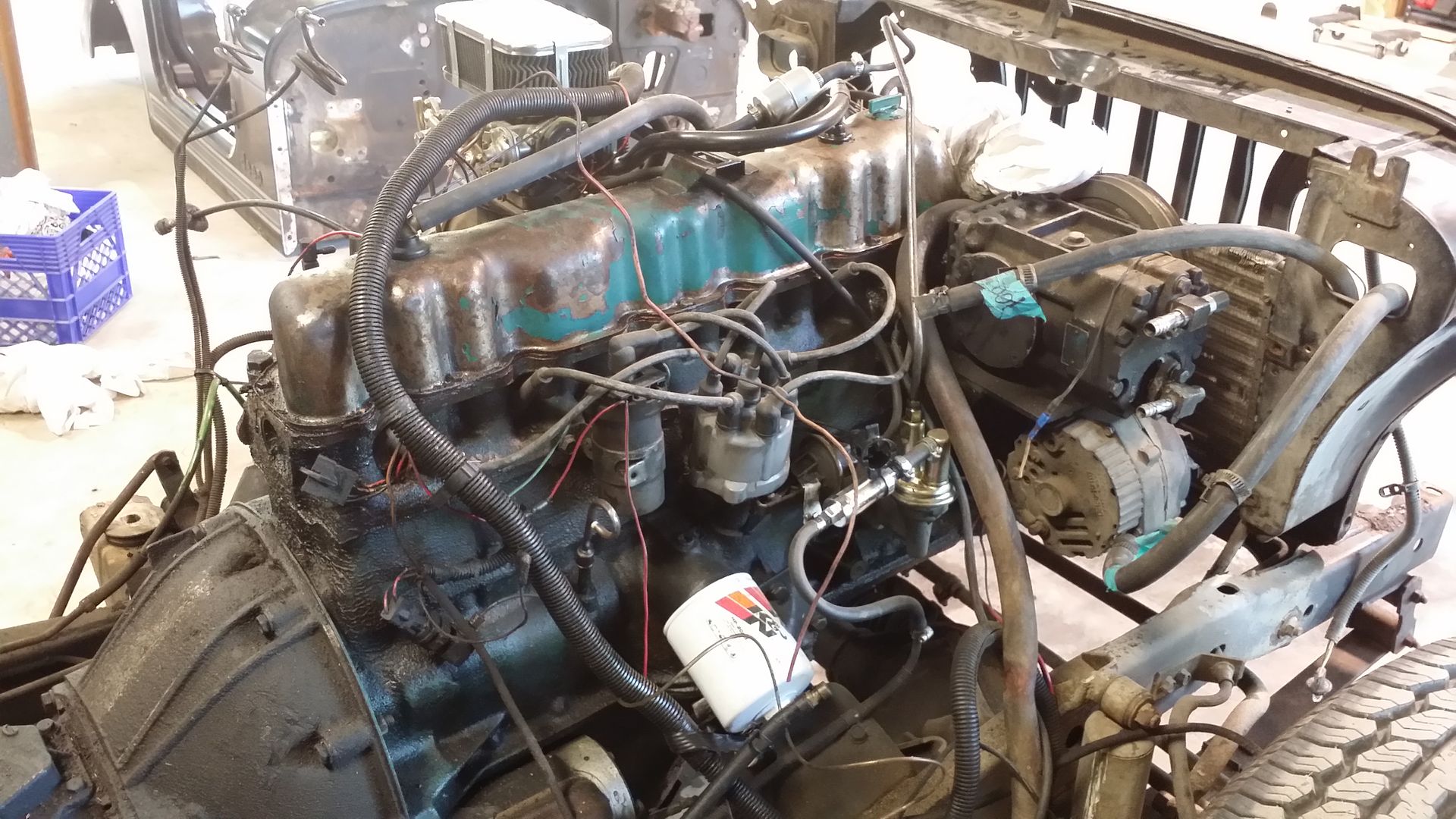

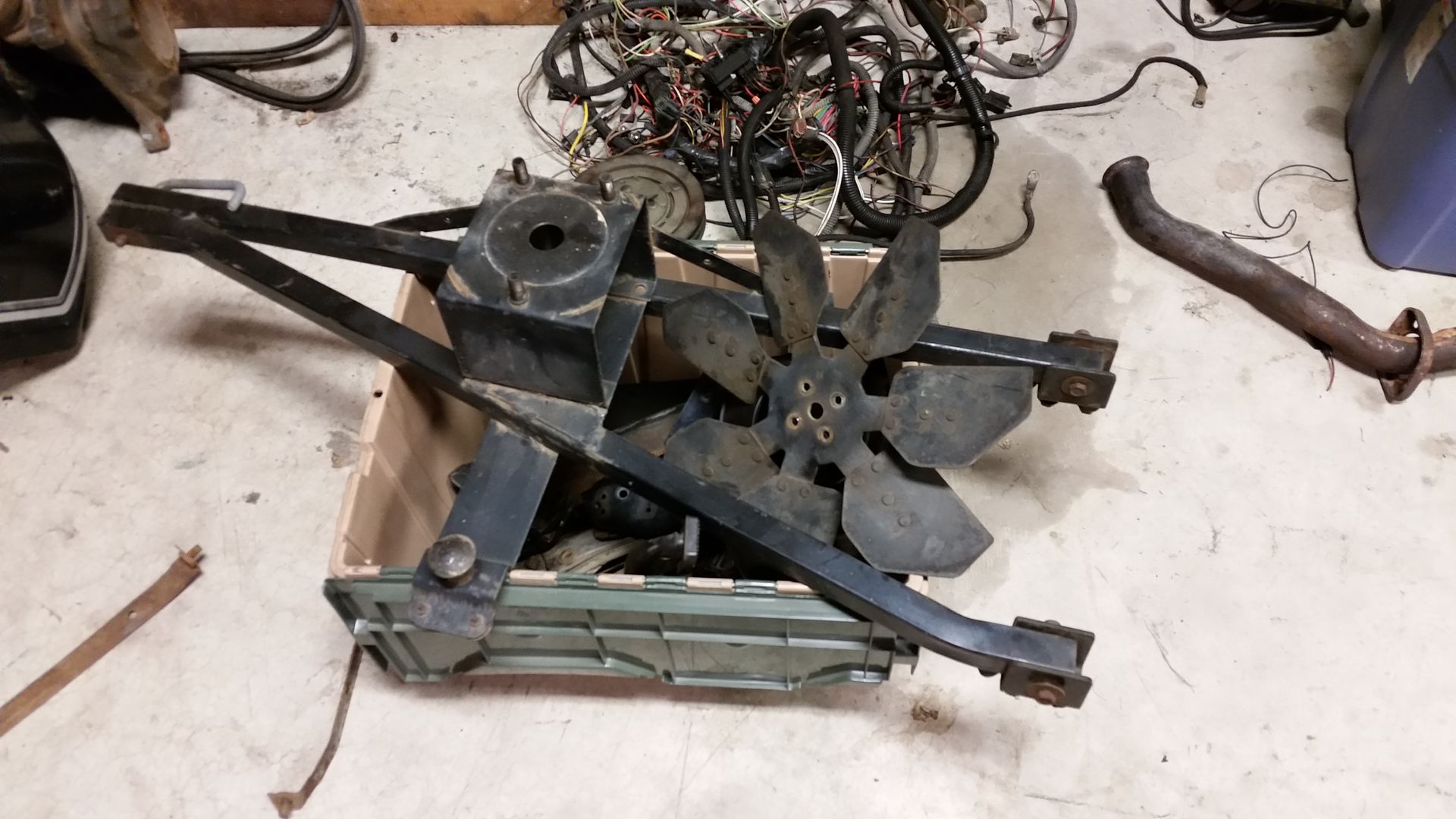

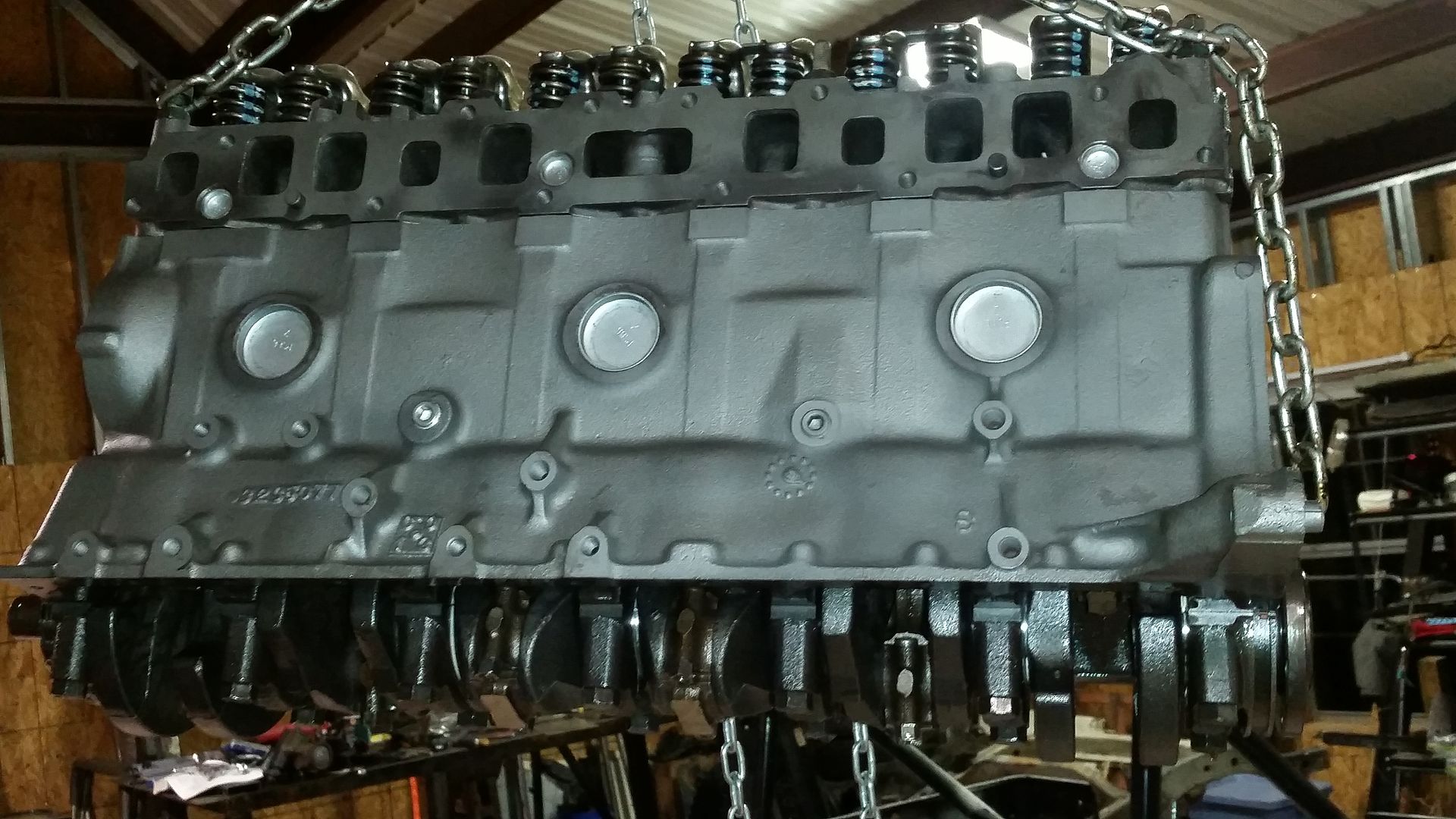

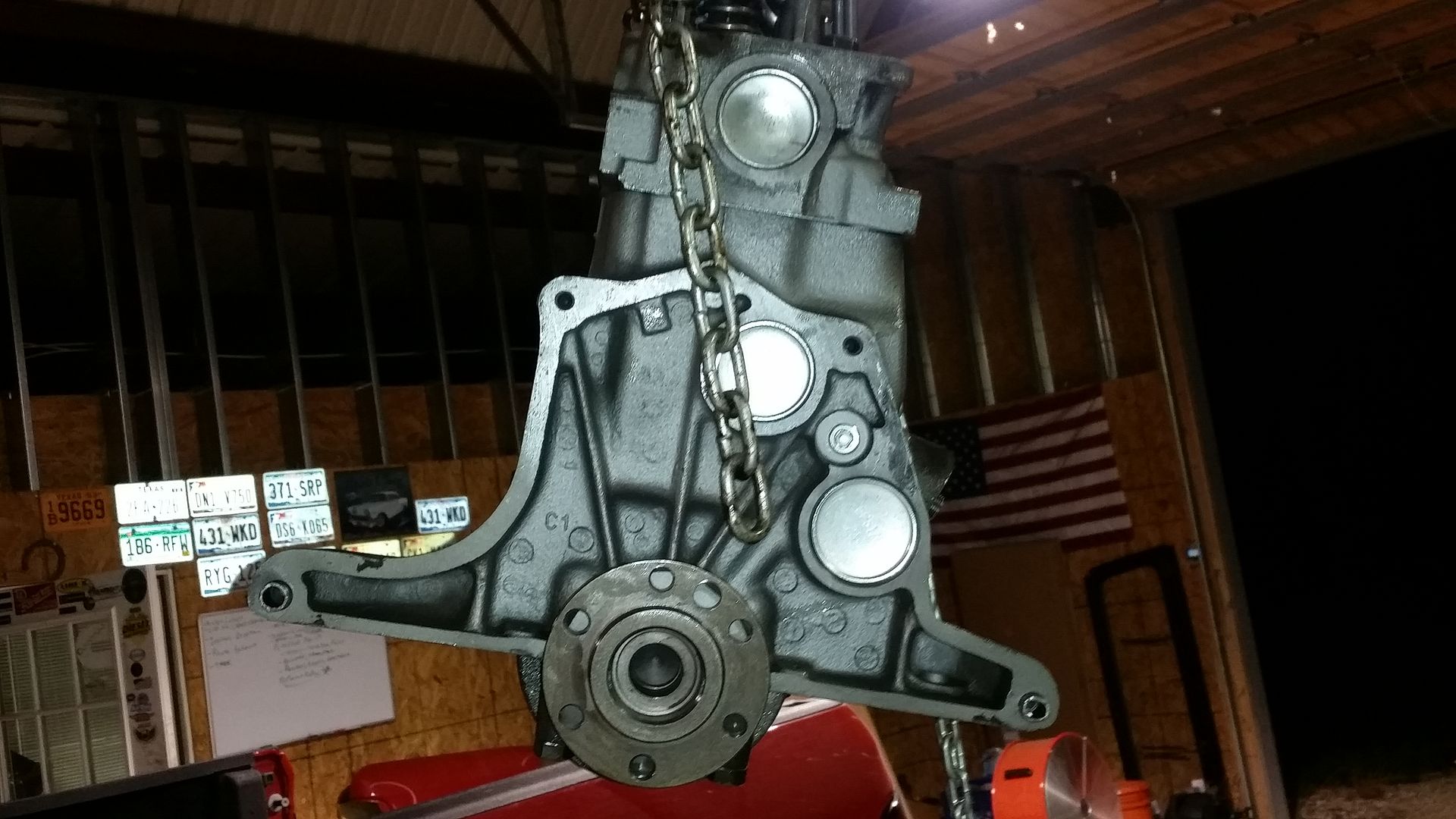

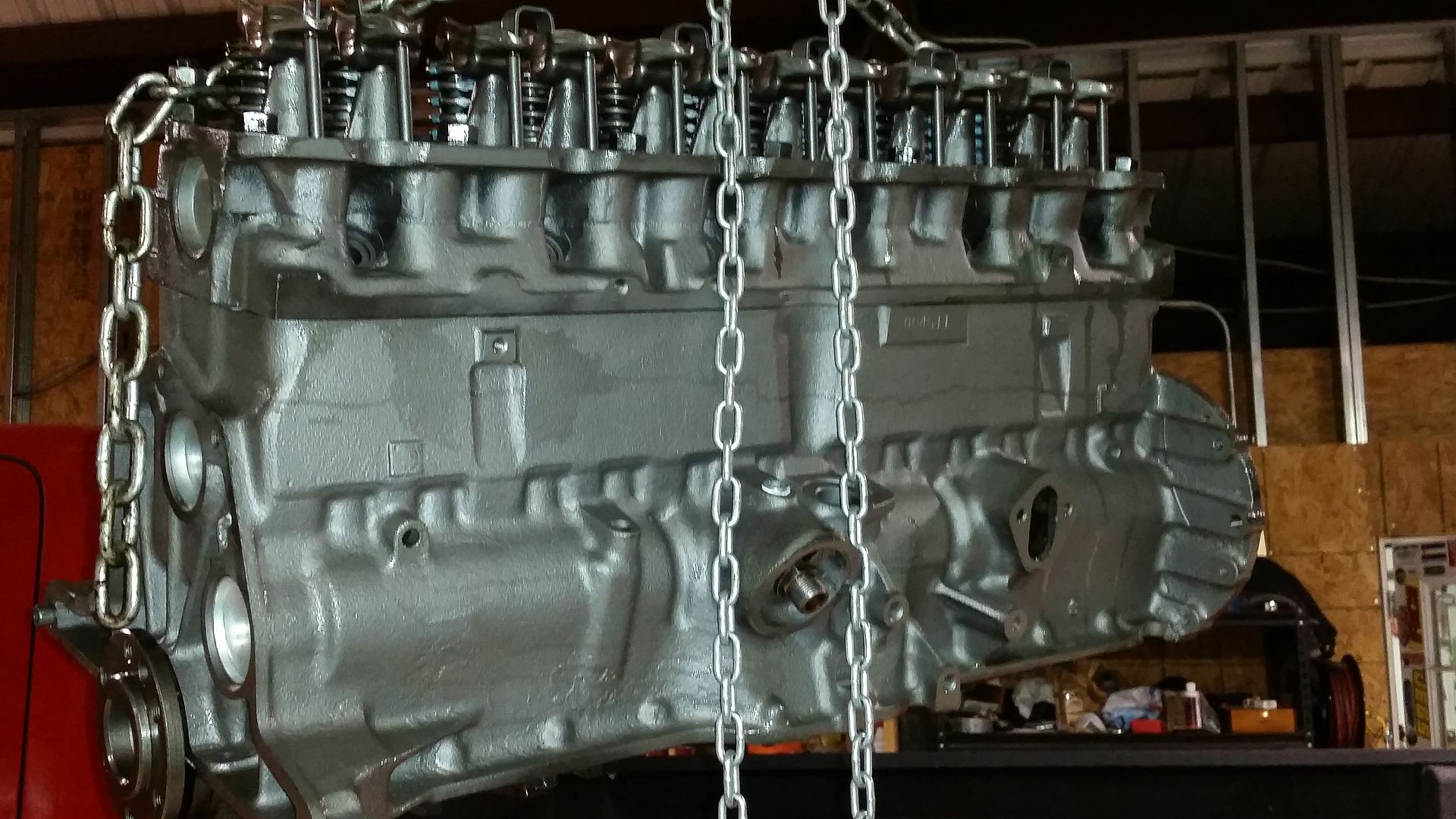

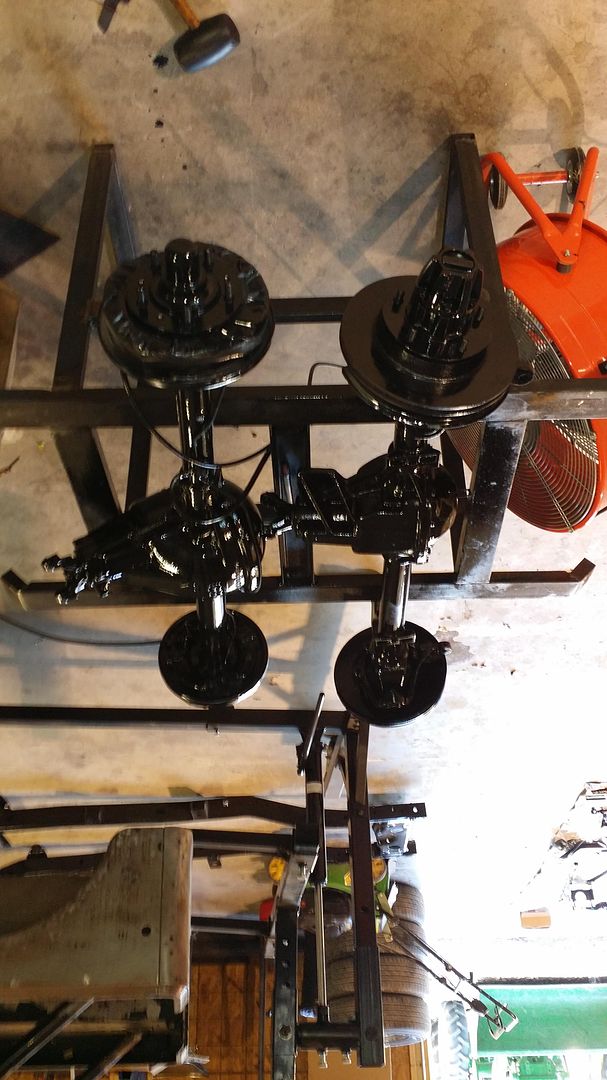

Then I got into the engine compartment. From the heads down to the rear axle was covered in oil that had congealed into a muddy-greasy mess. It was apparent that the engine would need to be pulled and rebuilt, not to mention the entire drive trained cleaned.

Based on these two things, the quick flip was dropped and plans for a full frame off restoration began.

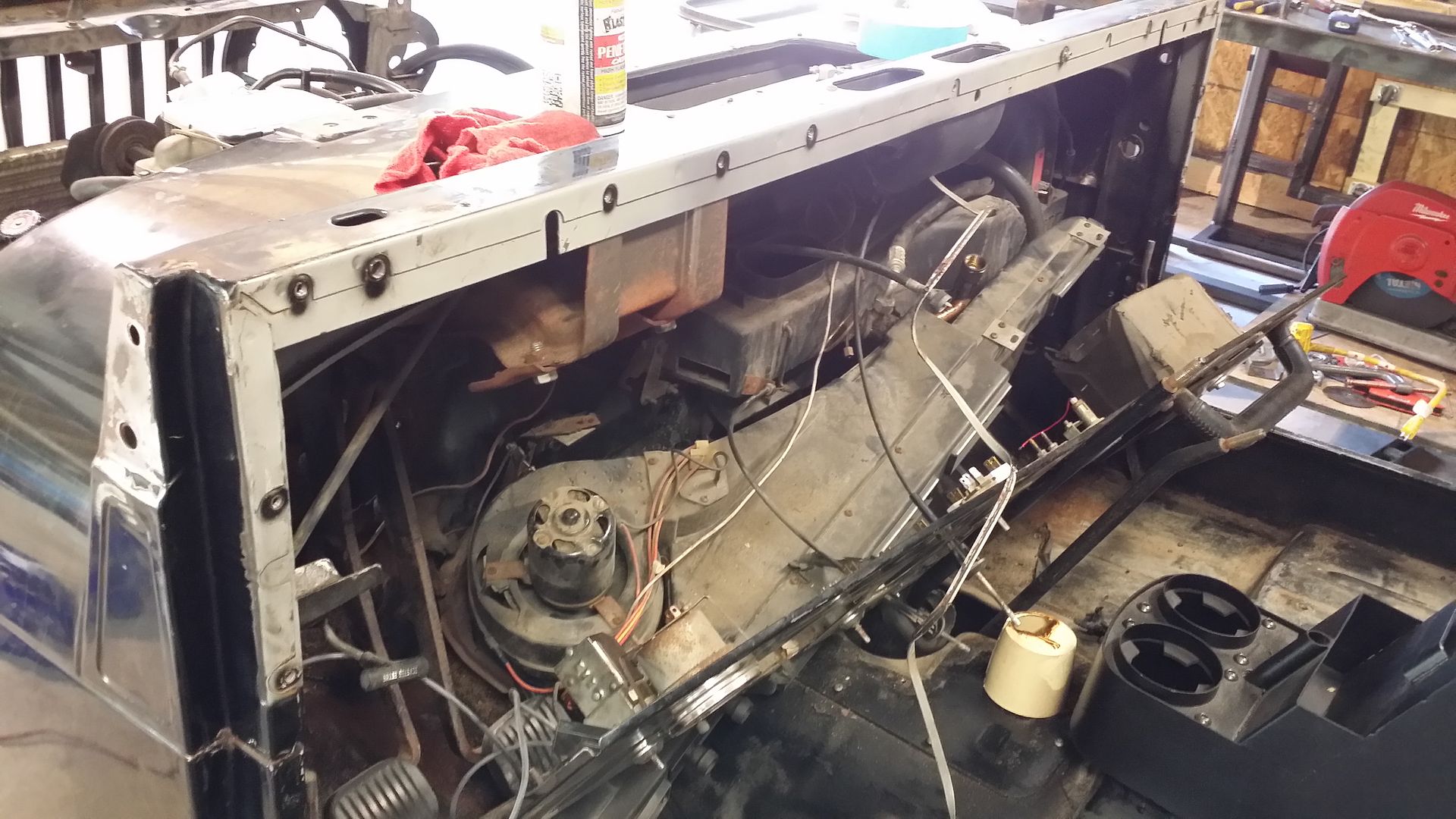

The body was relatively straight, save for a bad job on a rear end job from long ago. This is the same collision that had caused damage to the frame. There was some rot in the foot wells beneath the driver and passenger foot board from typical leaking CJ hard doors.

The interior seats and steering wheel were also in need of attention.

This Jeep lived most of its life in West Texas so the sun had damaged the clear coat, and bleached out the color coat.

Plans progressed quickly and so did the tear down.

This is the day I brought it home –

I picked this 1980 - CJ-7 up in April of 2014. My original plan was to increase its value by addressing its issues and flipping it for a quick profit.

When I began getting into it I realized that the frame was busted along the rear cross member and as I began removing suspension bolts, steering bolts, and other bolts inside the frame they would break off, free spin.

Then I got into the engine compartment. From the heads down to the rear axle was covered in oil that had congealed into a muddy-greasy mess. It was apparent that the engine would need to be pulled and rebuilt, not to mention the entire drive trained cleaned.

Based on these two things, the quick flip was dropped and plans for a full frame off restoration began.

The body was relatively straight, save for a bad job on a rear end job from long ago. This is the same collision that had caused damage to the frame. There was some rot in the foot wells beneath the driver and passenger foot board from typical leaking CJ hard doors.

The interior seats and steering wheel were also in need of attention.

This Jeep lived most of its life in West Texas so the sun had damaged the clear coat, and bleached out the color coat.

Plans progressed quickly and so did the tear down.

This is the day I brought it home –