You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Decorative Hawse fairlead 3D Printed

- Thread starter jal

- Start date

jal

Active Member

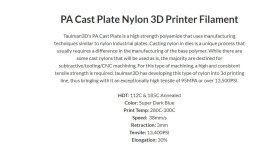

Yaaa I have that material as wellThat's super cool! UV stability will be a bigger problem than durability though. ABS will last slightly longer than PLA but I doubt either will make it more than a few months in direct sunlight. ASA is probably your best option plus it's about the same price as ABS.

ASA

Will update my findings

jal

Active Member

Not For FDM that I'm aware ofHave they made Delrin (POM) available for 3D printers yet?

kevman65

Hooked

Reason why I asked, motorcycle riders have been using frame sliders made of Delrin for years. It's a stout material, doesn't crack or splinter while it's being ground down and slowing the inertia of a sliding bike.Not For FDM that I'm aware of

CalSgt

Hooked

What's the melting point? How's the abrasion resistance? I would think a synthetic line would cut through that like a hot knife through butter. Especially on an off axis pull where you need the hawse most to guide the line back onto the spool and protect it from sharp edges of the bumper.

You might be amazed at the things that can be cut up and dismantled by someone a shoe lace...

ETA: This forum has generally all agreed that a winch is safety equipment and should not be skimped on... I'll add anything involved in winching is safety equipment and your life may depend on it someday. Just buy an aluminum one. Sorry to shit on your idea.

You might be amazed at the things that can be cut up and dismantled by someone a shoe lace...

ETA: This forum has generally all agreed that a winch is safety equipment and should not be skimped on... I'll add anything involved in winching is safety equipment and your life may depend on it someday. Just buy an aluminum one. Sorry to shit on your idea.

jal

Active Member

No worriesWhat's the melting point? How's the abrasion resistance? I would think a synthetic line would cut through that like a hot knife through butter. Especially on an off axis pull where you need the hawse most to guide the line back onto the spool and protect it from sharp edges of the bumper.

You might be amazed at the things that can be cut up and dismantled by someone a shoe lace...

ETA: This forum has generally all agreed that a winch is safety equipment and should not be skimped on... I'll add anything involved in winching is safety equipment and your life may depend on it someday. Just buy an aluminum one. Sorry to shit on your idea.

My business is in 3d printing so I always try new things

Spazbyt

Hooked

So I take it you won't be interested in my 3D printed snatch blocks then?What's the melting point? How's the abrasion resistance? I would think a synthetic line would cut through that like a hot knife through butter. Especially on an off axis pull where you need the hawse most to guide the line back onto the spool and protect it from sharp edges of the bumper.

You might be amazed at the things that can be cut up and dismantled by someone a shoe lace...

ETA: This forum has generally all agreed that a winch is safety equipment and should not be skimped on... I'll add anything involved in winching is safety equipment and your life may depend on it someday. Just buy an aluminum one. Sorry to shit on your idea.

CalSgt

Hooked

That checks out.changed the thread title to decorative

I was going to make a poser joke of some sort but the reality is the vast majority of Jeep owners or all 4x4 owners have never experienced any off road driving more technical or demanding than an unpaved driveway. The market for parts that "look cool" is undeniably massive and I don't blame you for wanting your Jeep to look cool.

I'd bet you could sell 3D printed winches for a decent chunk of change on Ebay or Etsy to people that just want to fill the ugly gap in their bumper. Upgrade options could include the hawse, and a 3 foot chunk of cable with a 3D printed hook to hang from a 3D printed bow shackle on a recovery point. Most everyone at the mall cant tell the difference anyway. Shit you'd probably be able to sell them to people for their SEMA builds.

jal

Active Member

I hear ya - not my thing-That checks out.

I was going to make a poser joke of some sort but the reality is the vast majority of Jeep owners or all 4x4 owners have never experienced any off road driving more technical or demanding than an unpaved driveway. The market for parts that "look cool" is undeniably massive and I don't blame you for wanting your Jeep to look cool.

I'd bet you could sell 3D printed winches for a decent chunk of change on Ebay or Etsy to people that just want to fill the ugly gap in their bumper. Upgrade options could include the hawse, and a 3 foot chunk of cable with a 3D printed hook to hang from a 3D printed bow shackle on a recovery point. Most everyone at the mall cant tell the difference anyway. Shit you'd probably be able to sell them to people for their SEMA builds.

I have had this brand/type bumper on my 2 previous Jeeps- and wanted to keep the tradition alive so to speak with this one-

The reason I printed this to start with is

1. because I can

2. I plan to have one milled out of aluminum and wanted it to be custom to my jeep an my tastes.

I can iterate changes and print for fitment etc etc

My business is a 3D printing service ( Spectra3D Technologies ) and we primarily print patterns for investment/ sand foundries as well as jigs and fixtures for manufactures across the country.

I have no desire to print fake parts for sale etc.

Since I can incorporate what I do for a living into making custom parts etc. for my Jeep , why not ...

Thats what makes Jeep and the Jeep community so great ..

I will update as I go along in this process.

Kenney

Member

You could buy an aluminum or steel Winch plate and print a decorative picture frame like a shim with your custom idea 3d printed on it (like a Dragon Head or Family Name)..I hear ya - not my thing-

I have had this brand/type bumper on my 2 previous Jeeps- and wanted to keep the tradition alive so to speak with this one-

The reason I printed this to start with is

1. because I can

2. I plan to have one milled out of aluminum and wanted it to be custom to my jeep an my tastes.

I can iterate changes and print for fitment etc etc

My business is a 3D printing service ( Spectra3D Technologies ) and we primarily print patterns for investment/ sand foundries as well as jigs and fixtures for manufactures across the country.

I have no desire to print fake parts for sale etc.

Since I can incorporate what I do for a living into making custom parts etc. for my Jeep , why not ...

Thats what makes Jeep and the Jeep community so great ..

I will update as I go along in this process.

Attachments

jal

Active Member

You could buy an aluminum or steel Winch plate and print a decorative picture frame like a shim with your custom idea 3d printed on it (like a Dragon Head or Family Name)..