If you've just installed a brand new lift on your Jeep JL Wrangler and are wanting to get it aligned, there are a couple of things you should know before you take it to a shop and pay to have it done. First, unless you've installed new aftermarket components such as an adjustable track bar and/or adjustable control arms, there really isn't a whole lot a shop can to other than recenter your steering wheel and take your money. Due to the design of the JL steering system, your toe-in will not change at all and being that it comes with a solid front axle, its camber will not change either. Depending on how much lift you install, your caster may be off enough to feel it but again, nothing can be done unless you've installed aftermarket components that will allow you to make adjustments. Second, even if you have installed a 2" lift or taller and added adjustable components, doing a basic front end alignment is easy, something you can do in your own driveway, with the use of some basic tools and this write-up will show you how.

Alignment Topics

Steering Wheel Re-centering

Front Axle Re-centering

Setting Caster

Setting Toe-In

What You Will Need

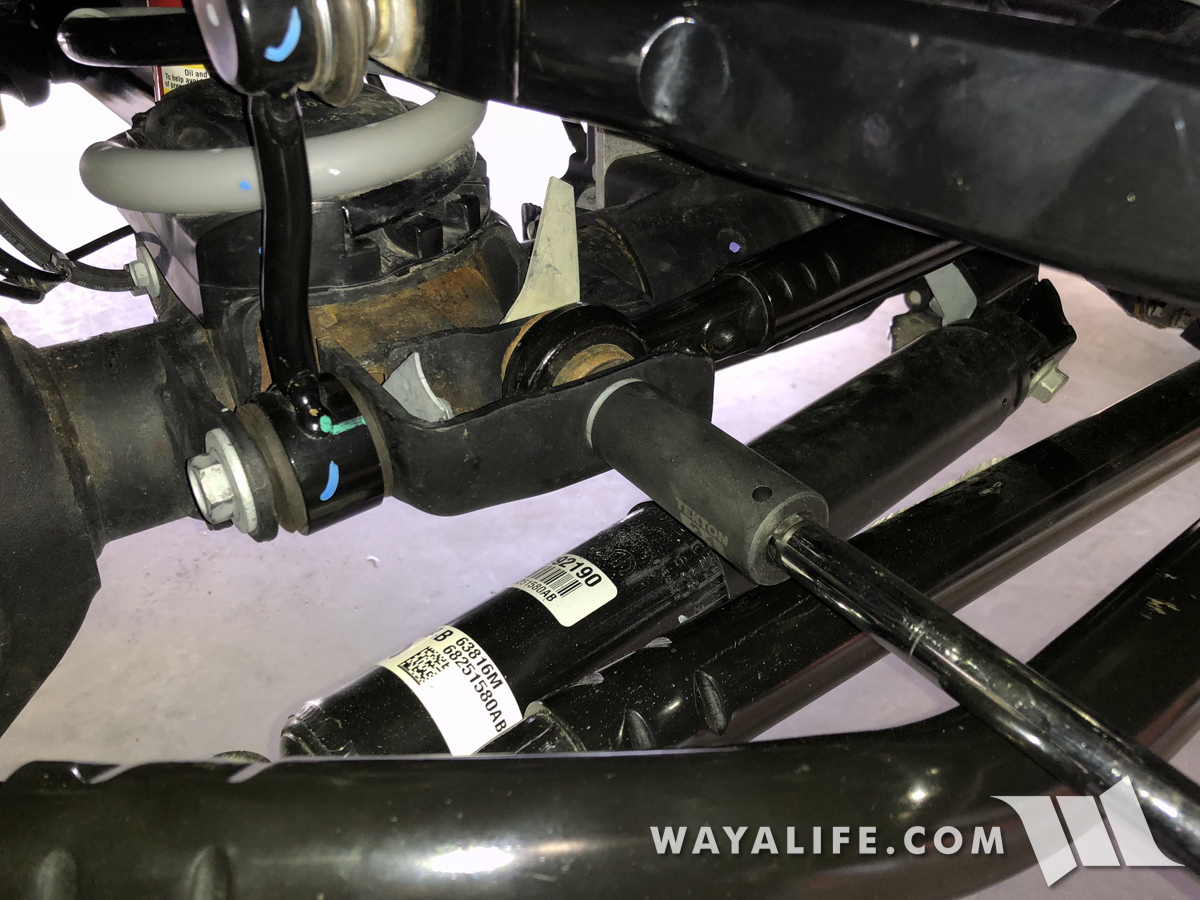

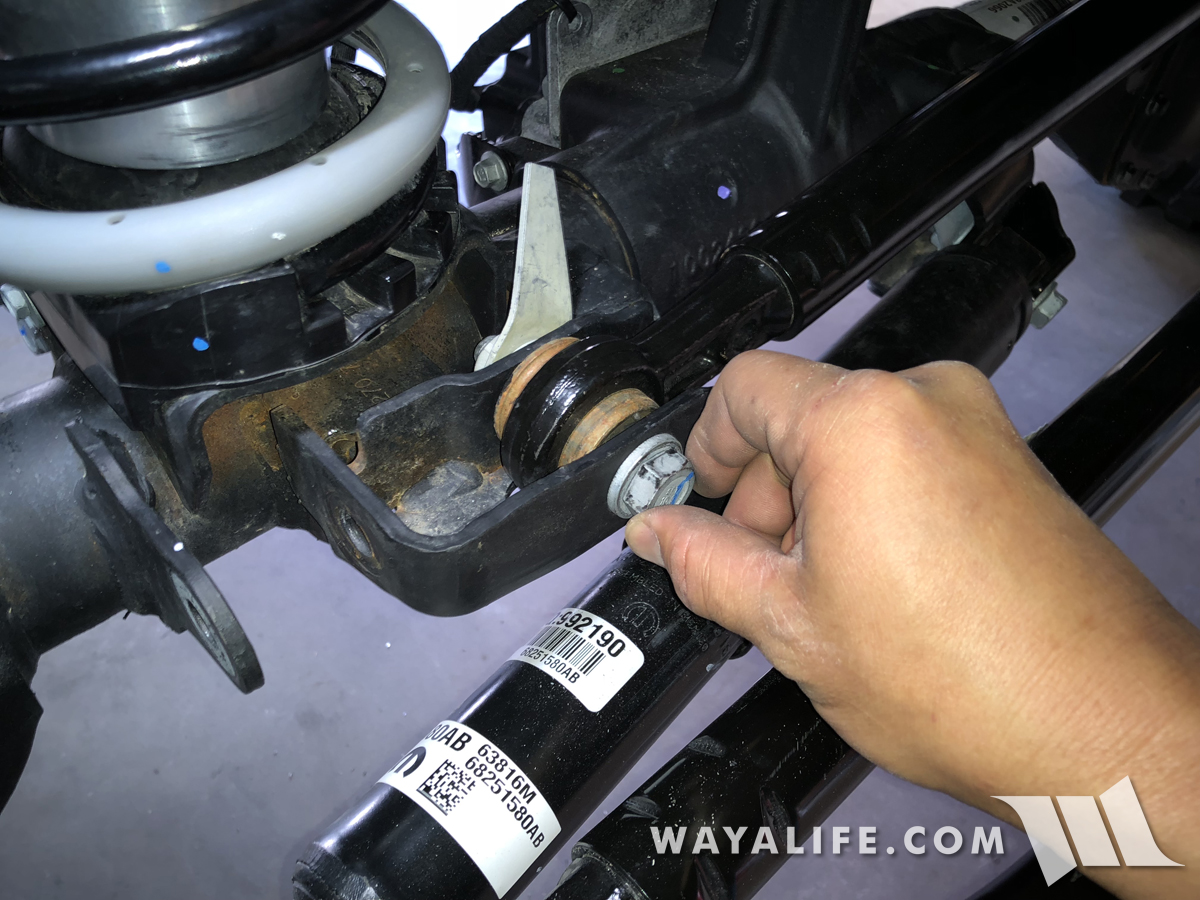

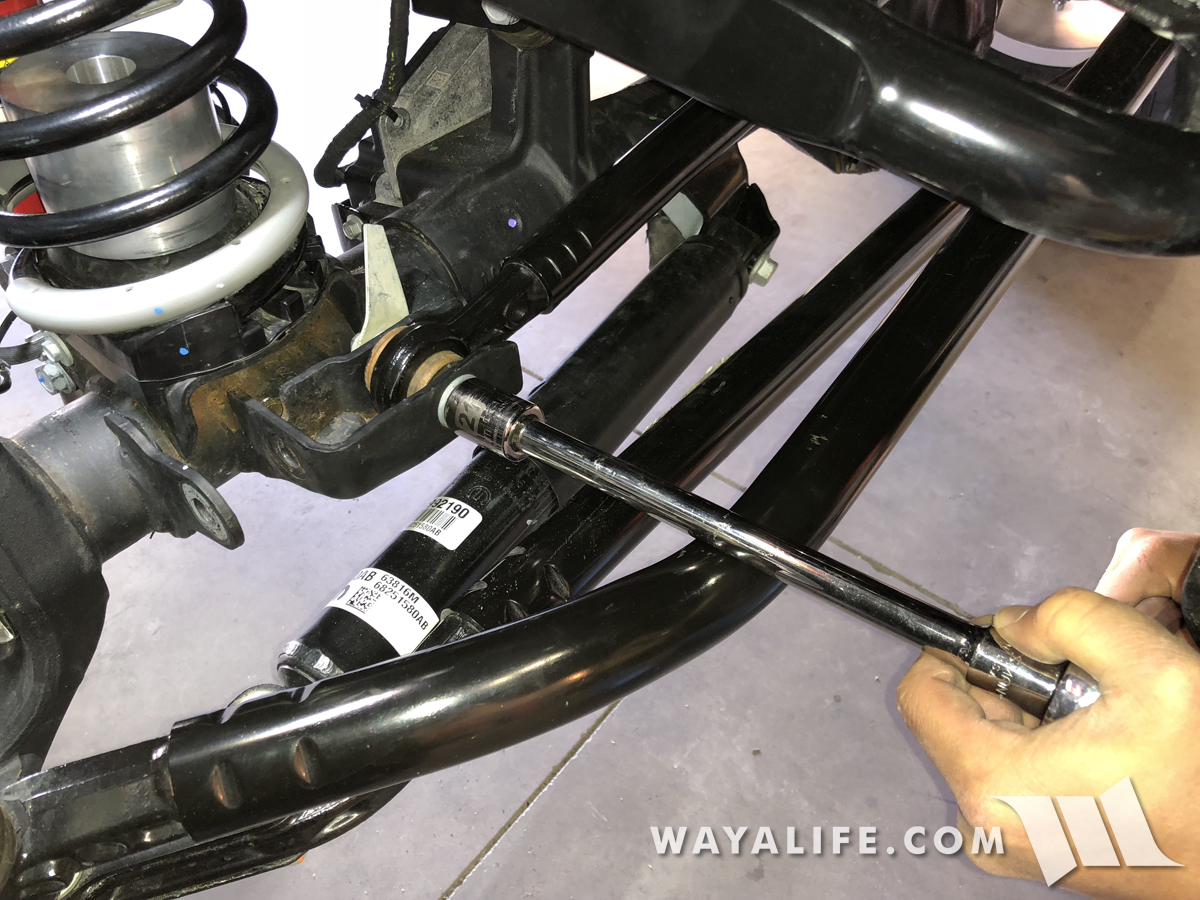

• 15,18,21,24mm Socket & Wrench

• Ratchet

• Large Crescent Wrench

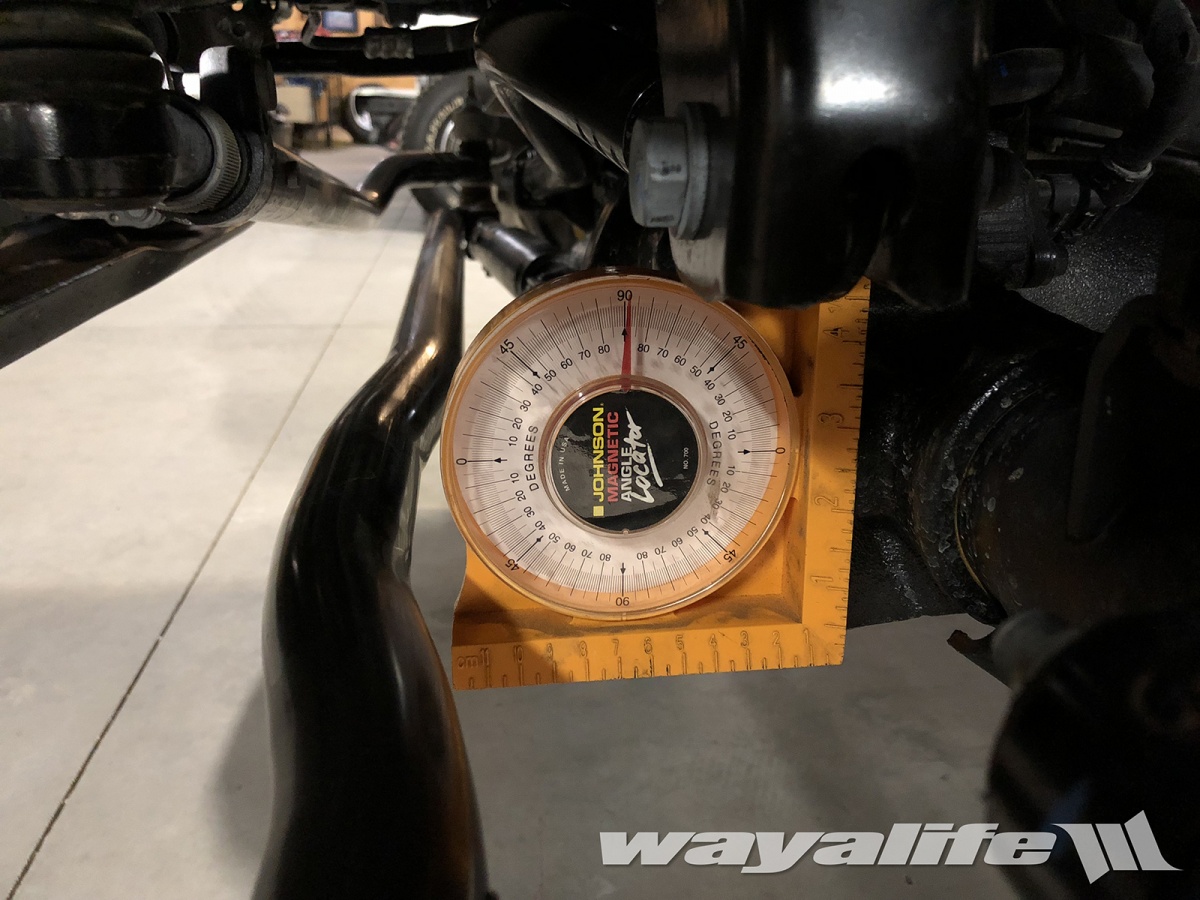

• Angle Finder

• Tape Measure

• Carpenters Level

• Floor Jack

• Jack Stands

Alignment Definitions

The following are common wheel alignment definitions as defined by Jeep and that you will need to be familiar with:

CASTER is the forward or rearward tilt of the steering knuckle from vertical. Tilting the top of the knuckle rearward provides positive caster. Tilting the top of the knuckle forward provides negative caster. Caster is a directional stability angle. This angle enables the front wheels to return to a straight ahead position after turns.

CAMBER is the inward or outward tilt of the wheel relative to the center of the vehicle. Tilting the top of the wheel inward provides negative camber. Tilting the top of the wheel outward provides positive camber. Incorrect camber will cause wear on the inside or outside edge of the tire. The angle is not adjustable, damaged component(s) must be replaced to correct the camber angle.

WHEEL TOE POSITION is the difference between the leading inside edges and trailing inside edges of the front tires. Incorrect wheel toe position is the most common cause of unstable steering and uneven tire wear. The wheel toe position is the final front wheel alignment adjustment.

STEERING AXIS INCLINATION ANGLE is measured in degrees and is the angle that the steering knuckles are tilted. The inclination angle has a fixed relationship with the camber angle. It will not change except when a spindle or ball stud is damaged or bent. The angle is not adjustable, damaged component(s) must be replaced to correct the steering axis inclination angle.

THRUST ANGLE is the angle of the rear axle relative to the centerline of the vehicle. Incorrect thrust angle can cause off-center steering and excessive tire wear. This angle is not adjustable, damaged component(s) must be replaced to correct the thrust angle.

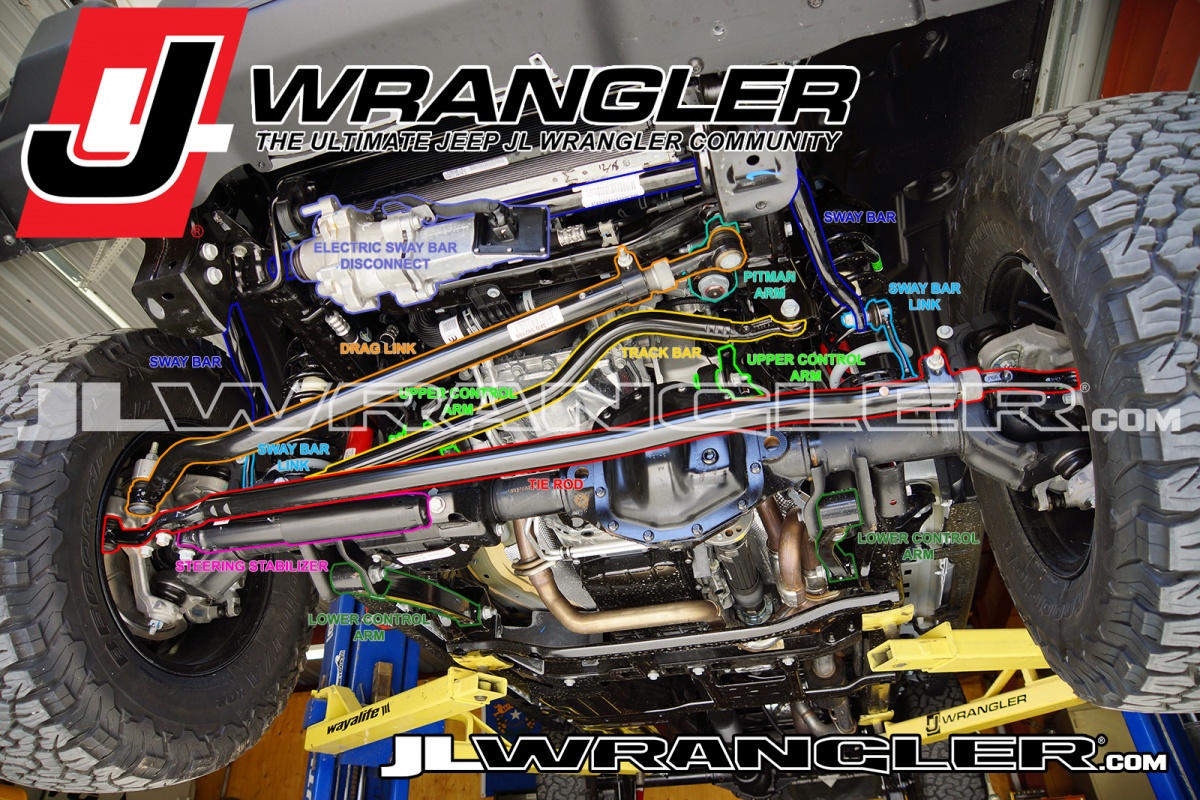

Alignment Diagrams

Diagram from Jeep JL Wrangler Factory Service Manual.

Disclaimer: Utmost care should be taken when modifying anything to your suspension. Injury to you, your Jeep, and/or others can result from improper suspension modifications or alterations. The author is not a certified mechanic and assumes no responsibility for damage or injury.

Last edited: