MSJKU11

Caught the Bug

So I recently acquired a Jeep OE Warn 8274 from a 78 CJ. I made this thread to document my process of restoring it in case anyone was doing the same or interested in reading. My plan is to rebuild the brake, replace the seals and whatever components that need to be replaced. I also plan on modifying my front bumper on my JK to mount it on the front. I understand it's probably not the most popular idea but it's something I've been wanting to do.

First step is going to be the breakdown of the winch to prepare it for media blasting and paint and repair any broken/worn out components.

I first removed the cable by removing the end cap and the clamp holding the line. I plan on moving to synthetic line and the cable had several frayed sections I decided to throw this out.

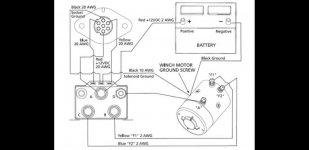

Remove the control box by removing the leads and the clamps holding it against the motor.

To remove the motor you have to remove the two long bolts on the end and it should slide out through the armature bearing.

Remove the brake pawl. Remove the top and pull out the spring and keep. Mine was missing a zerg fitting so I'll have to replace it.

Remove the clutch by unbolting the 4 bolts around it and it should pull out with the key attached or it may fall to the bottom which is okay. You may have to use some blaster but you'll have to unscrew the handle and slide the clutch out of the mounting hole. There will be a spring and small bearing you'll need to remove and clean and keep to the side. No replacements available so if you lose it you'll have to buy a whole new clutch.

Remove the two halves of the casings by remove the surrounding 3 bolts. You might need to use some leverage to pull them apart due to the sealant. I just used a long screwdriver.

Since my armature bearing was pretty rusted I decided to remove it and replace with a new one. Simply hammer it out from the inside. There is a lip so you wont be able to hammer it from the outside.

To tackle the brake and depending on the rust it's probably the hardest and longest part. You'll want to blast it first and then take off the c clamp.

I was unable to remove it by hand so I used a metal clamp to hold it in place and hammer it out. You can also use a puller but I didn't have one at the time. Be careful when taking the brake apart because the bearing will fall all over the place, place it over a bucket to catch them to make it easier.

Remove the brake shaft by lifting up on the retainer plate that's against the casing and push it out with a flat head screwdriver. Might take a couple thrusts to push it out.

I forgot to take a picture but the drum will slide out and you just need to remove the nylon and rubber seals from the drum. Hammer out the nylon seal where the drum is inserted into the casing.

Now it's time to clean up everything, media blast it, and paint it.

First step is going to be the breakdown of the winch to prepare it for media blasting and paint and repair any broken/worn out components.

I first removed the cable by removing the end cap and the clamp holding the line. I plan on moving to synthetic line and the cable had several frayed sections I decided to throw this out.

Remove the control box by removing the leads and the clamps holding it against the motor.

To remove the motor you have to remove the two long bolts on the end and it should slide out through the armature bearing.

Remove the brake pawl. Remove the top and pull out the spring and keep. Mine was missing a zerg fitting so I'll have to replace it.

Remove the clutch by unbolting the 4 bolts around it and it should pull out with the key attached or it may fall to the bottom which is okay. You may have to use some blaster but you'll have to unscrew the handle and slide the clutch out of the mounting hole. There will be a spring and small bearing you'll need to remove and clean and keep to the side. No replacements available so if you lose it you'll have to buy a whole new clutch.

Remove the two halves of the casings by remove the surrounding 3 bolts. You might need to use some leverage to pull them apart due to the sealant. I just used a long screwdriver.

Since my armature bearing was pretty rusted I decided to remove it and replace with a new one. Simply hammer it out from the inside. There is a lip so you wont be able to hammer it from the outside.

To tackle the brake and depending on the rust it's probably the hardest and longest part. You'll want to blast it first and then take off the c clamp.

I was unable to remove it by hand so I used a metal clamp to hold it in place and hammer it out. You can also use a puller but I didn't have one at the time. Be careful when taking the brake apart because the bearing will fall all over the place, place it over a bucket to catch them to make it easier.

Remove the brake shaft by lifting up on the retainer plate that's against the casing and push it out with a flat head screwdriver. Might take a couple thrusts to push it out.

I forgot to take a picture but the drum will slide out and you just need to remove the nylon and rubber seals from the drum. Hammer out the nylon seal where the drum is inserted into the casing.

Now it's time to clean up everything, media blast it, and paint it.