REVERE THE STEER - Rubicat Going Wide with 72.5" Dynatrac XD60 / PRO 1550 Front Axle

Just because everyone and their mother runs big offset wheels with 4" of back spacing or less, doesn't mean it's necessarily a good idea. While pushing the center line of your wheels further out will help you to run bigger tires and without rubbing issues, you do it at the expense of increasing your scrub radius and at the cost of putting more stress on your ball joints, wheel bearings and even tie-rod. Of course, for most in the industry, that's just the way things have always been done, but for Dynatrac, it's a problem they wanted to solve. As luck would have it, Cindy and I would get a chance to help them do just that and with the assistance of Rubicat.

Bigger & Better

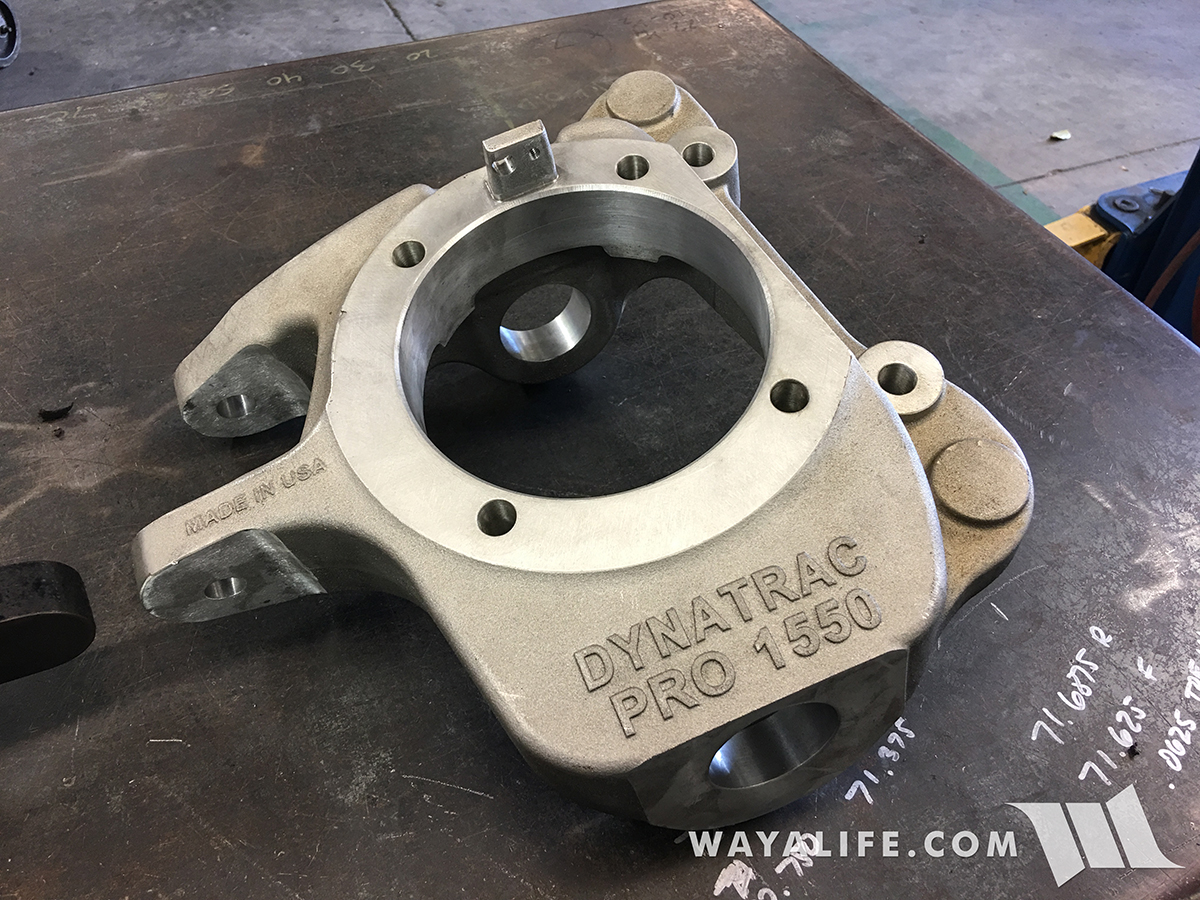

In addition to it's superior strength and significant weight savings, the Dynatrac PRO 1550 steering knuckle was specifically designed so that the steering axis inclination (the imaginary line you can draw through the axis of your ball joints) would meet at a point that's a lot closer to the center line of your wheel. By doing this, your wheels will pivot more instead of scrubbing as you make a turn and that alone helps to provide for much better steering and reduced stress on your tie-rod. In fact, the more back spacing you can run on a wheel (5.5" is optimal), the better everything will work especially with a set of 40" tires.

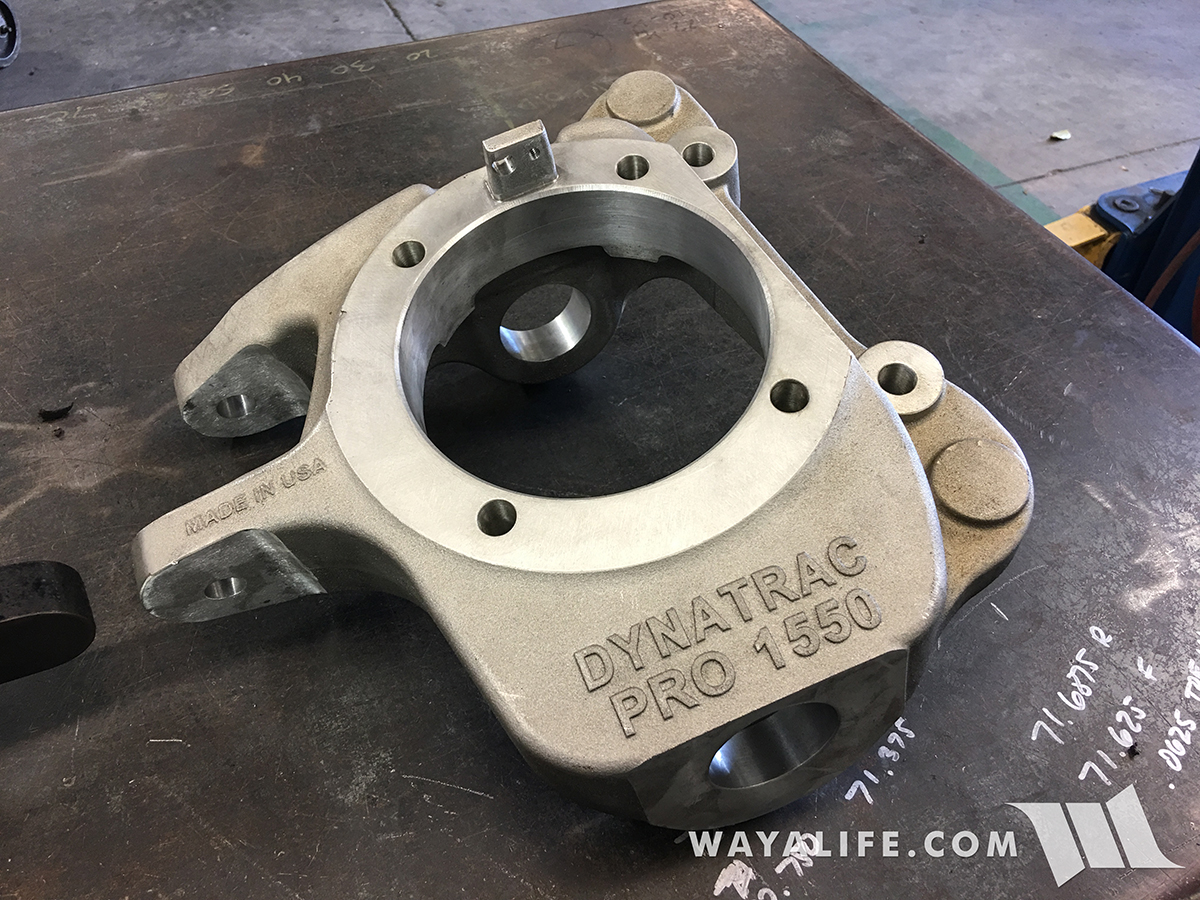

Just to give you an idea of how much bigger a Dynatrac PRO 1550 is than a factory steering knuckle, here's a side by side shot of of the two. If you can believe it, the difference between the two is only about 1.5 lbs. and this in spite of the PRO 1550's massive size.

Now, this is a side by side shot of standard PRO 60 steering knuckle on the left and a PRO 1550 on the right. As you can see, the opening is considerably wider on the PRO 1550 and this is to allow for a much bigger shaft. Also, because the PRO 1550 is made out of military grade aluminum instead of nodular iron like the PRO 60, it weighs about 8 lbs. less!

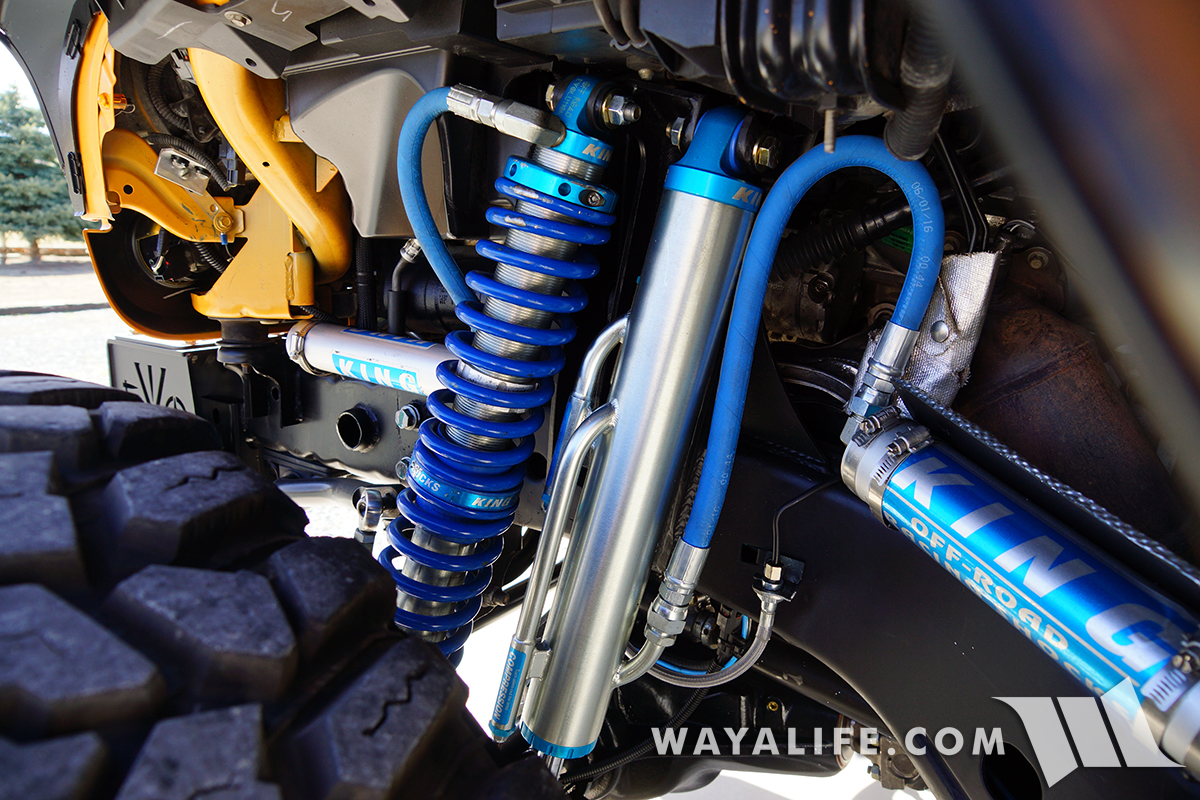

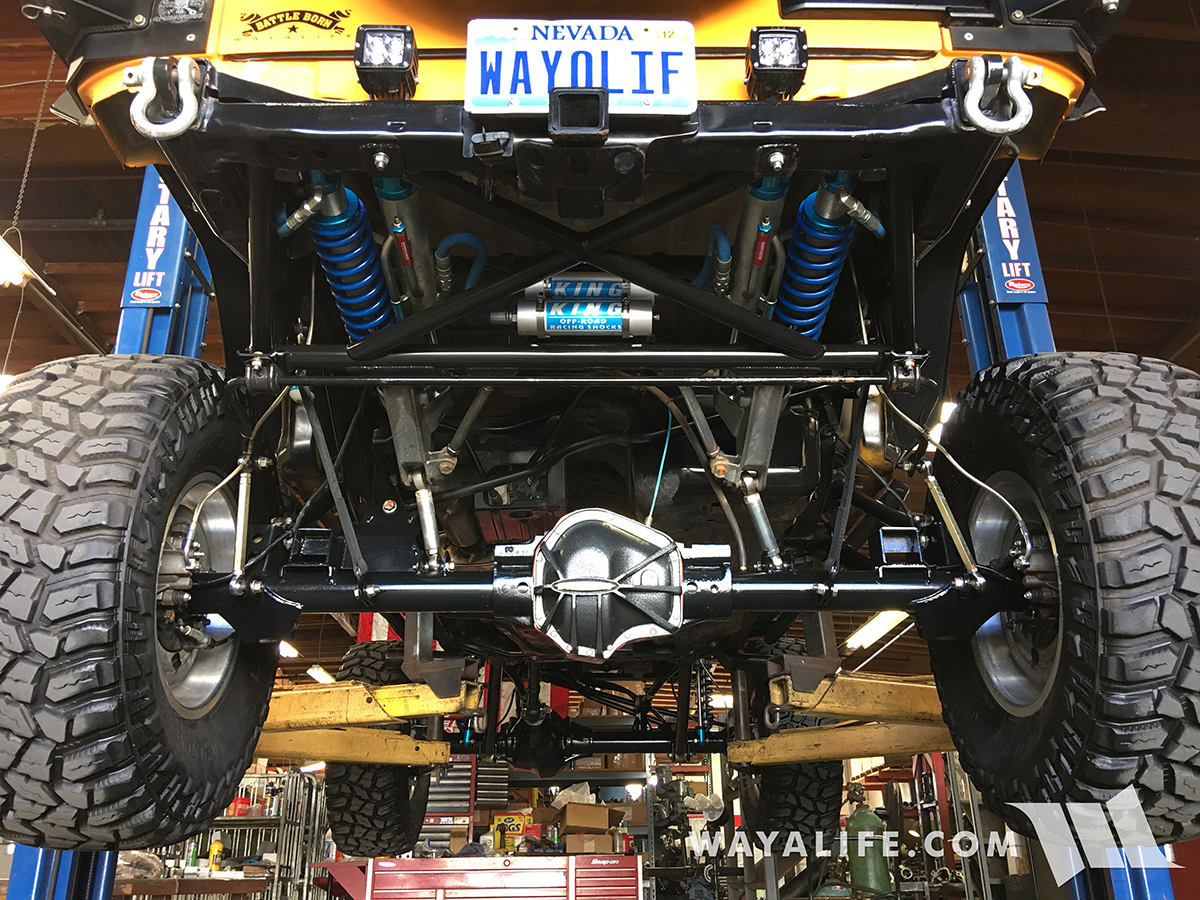

While the PRO 1550 steering knuckles alone will help improve your steering and a set of wheels with 5.5" of back spacing would make it that much better, Dynatrac understood that there are a lot of folks running coil over systems like the EVO DTD, Cindy and I included, and that this setup would prove to be a problem. To help address it, they decided to create a new version of their awesome XD60 that is wider... a LOT wider! For reference, a factory axle measures 65.5" wide and it can be difficult to run big wide tires or a coil over kit like the EVO DTD without running wheels with very little back spacing and in some cases, wheels spacers on top of them. A standard full width axle like a Dynatrac ProRock 60, XD60 or ProRock 80 will have a width of 68.5" and while the extra 3" will make it possible to run wheels with more backspacing, you'd still end up rubbing the bypass shocks on a EVO DTD setup with anything more than 3.5". This new version of the XD60 comes in a huge 72.5" width - that's a whole 4" wider than a standard full width axle and that will allow you to run a wheel with a whopping 5.5" of backspacing and without any rubbing!

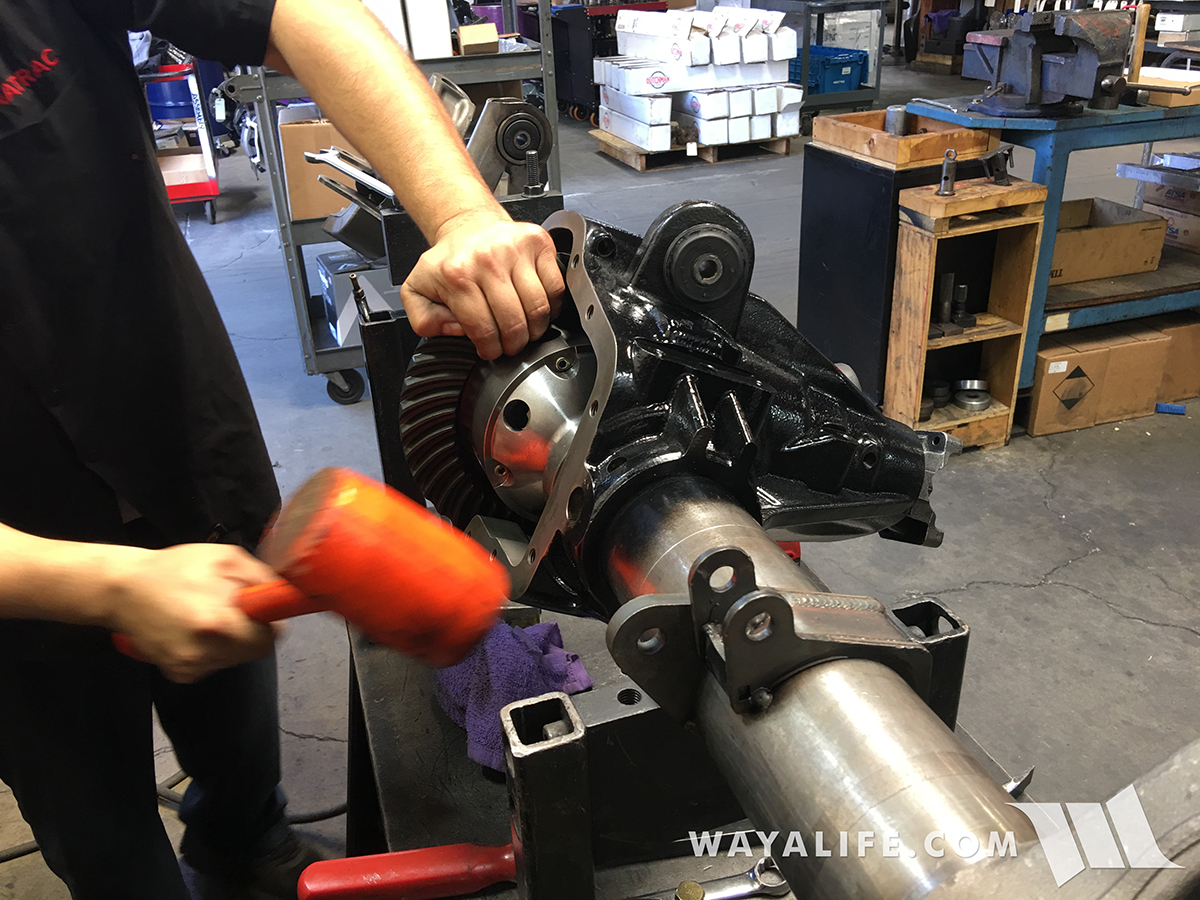

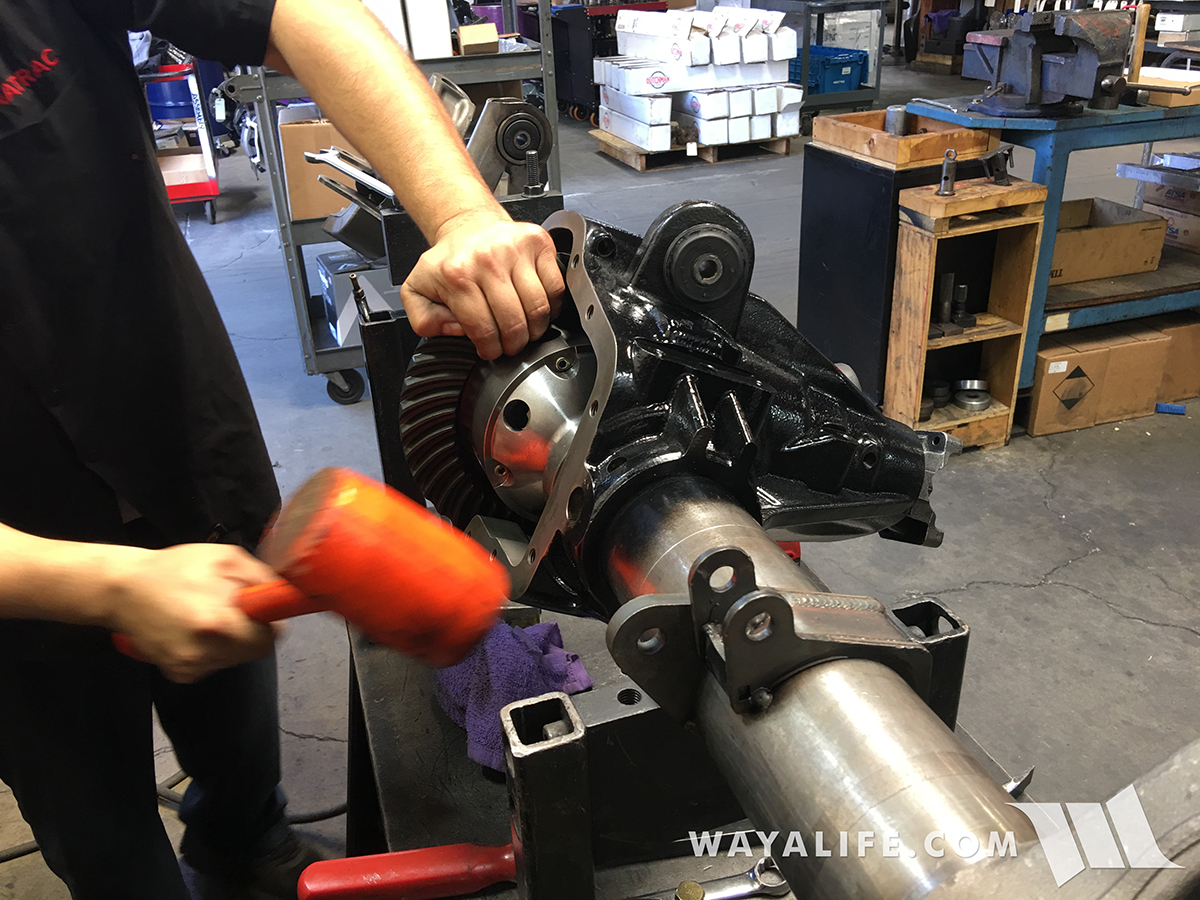

If you're gonna buy a Dynatrac axle, it's always best to have one that's not only built by them but assembled by one of their technicians as well.

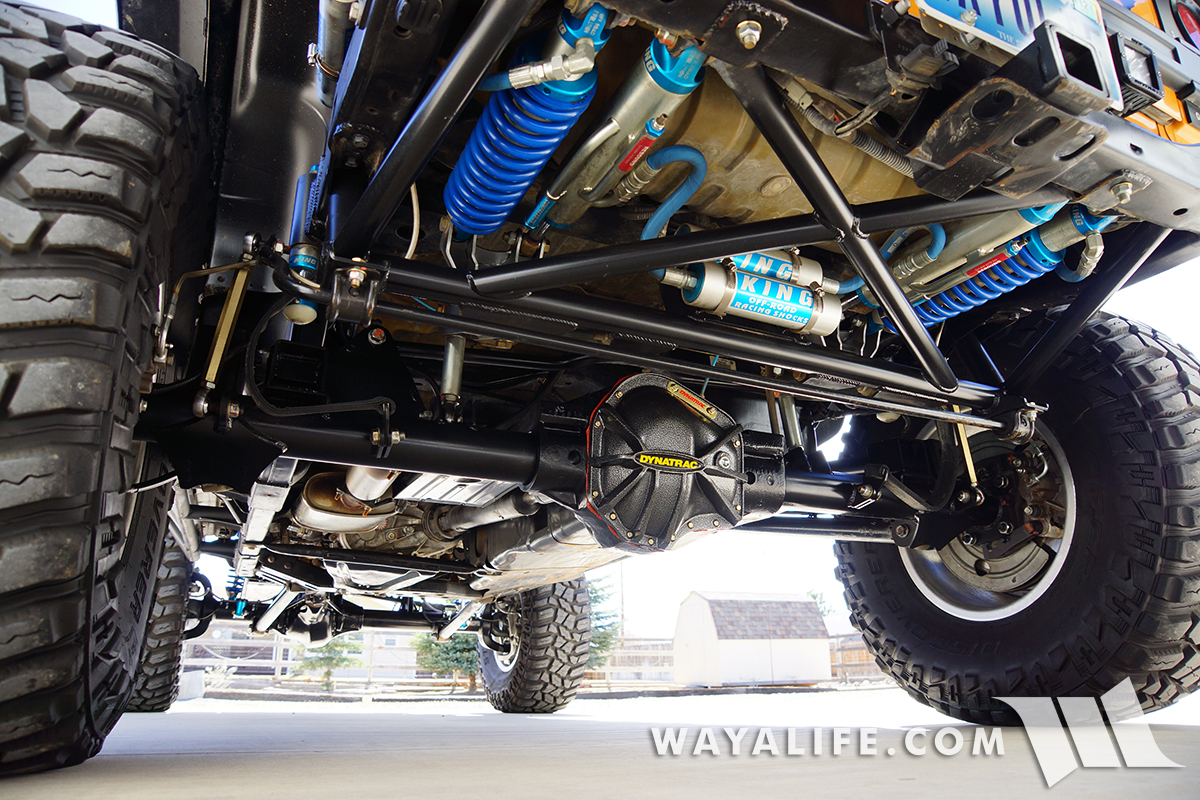

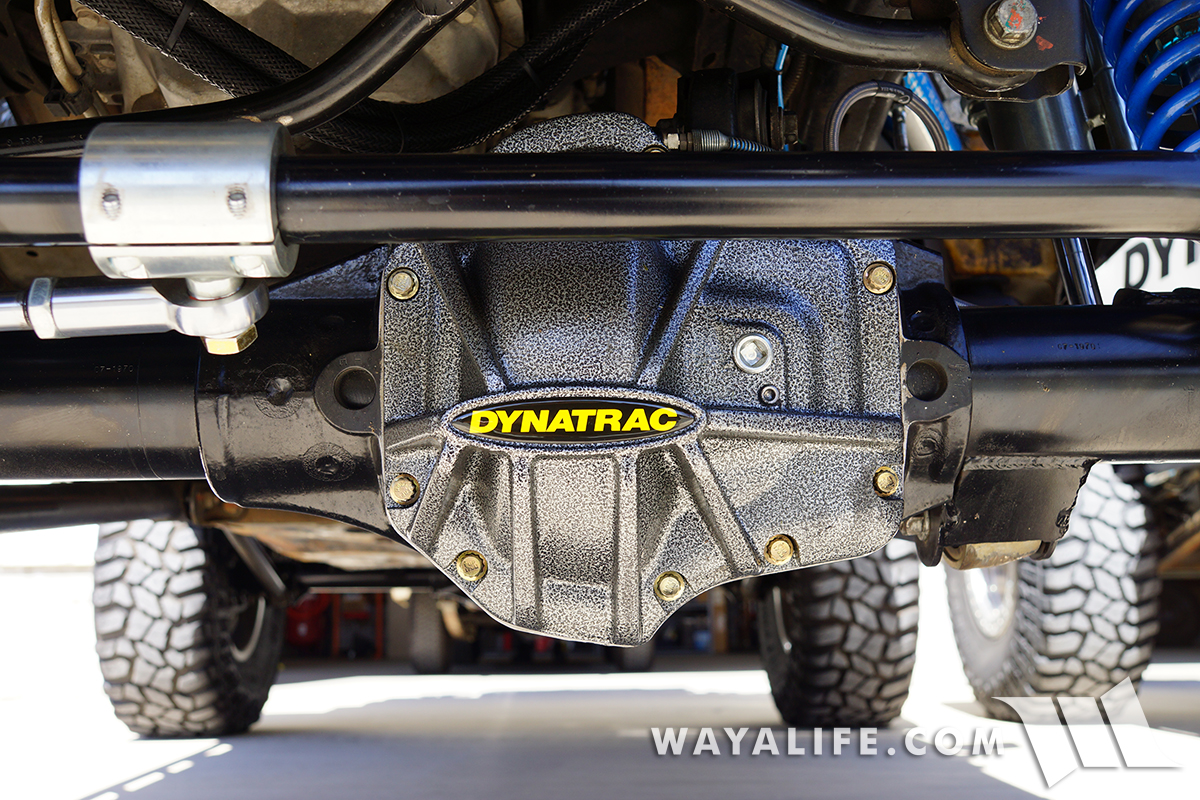

Gotta love the XD60 differential cover in that it not only comes with a cool o-ring but it also comes with significantly bigger bolts that get torqued on and is used to help strengthen the entire housing.

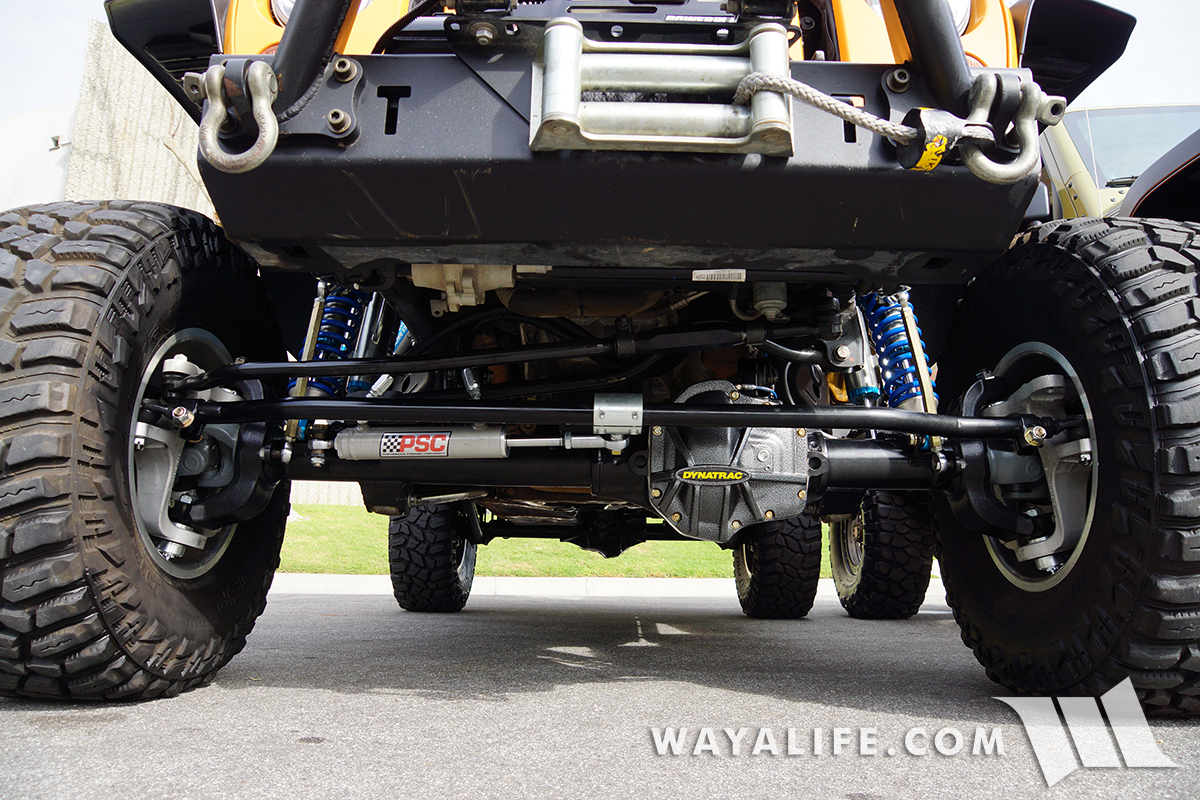

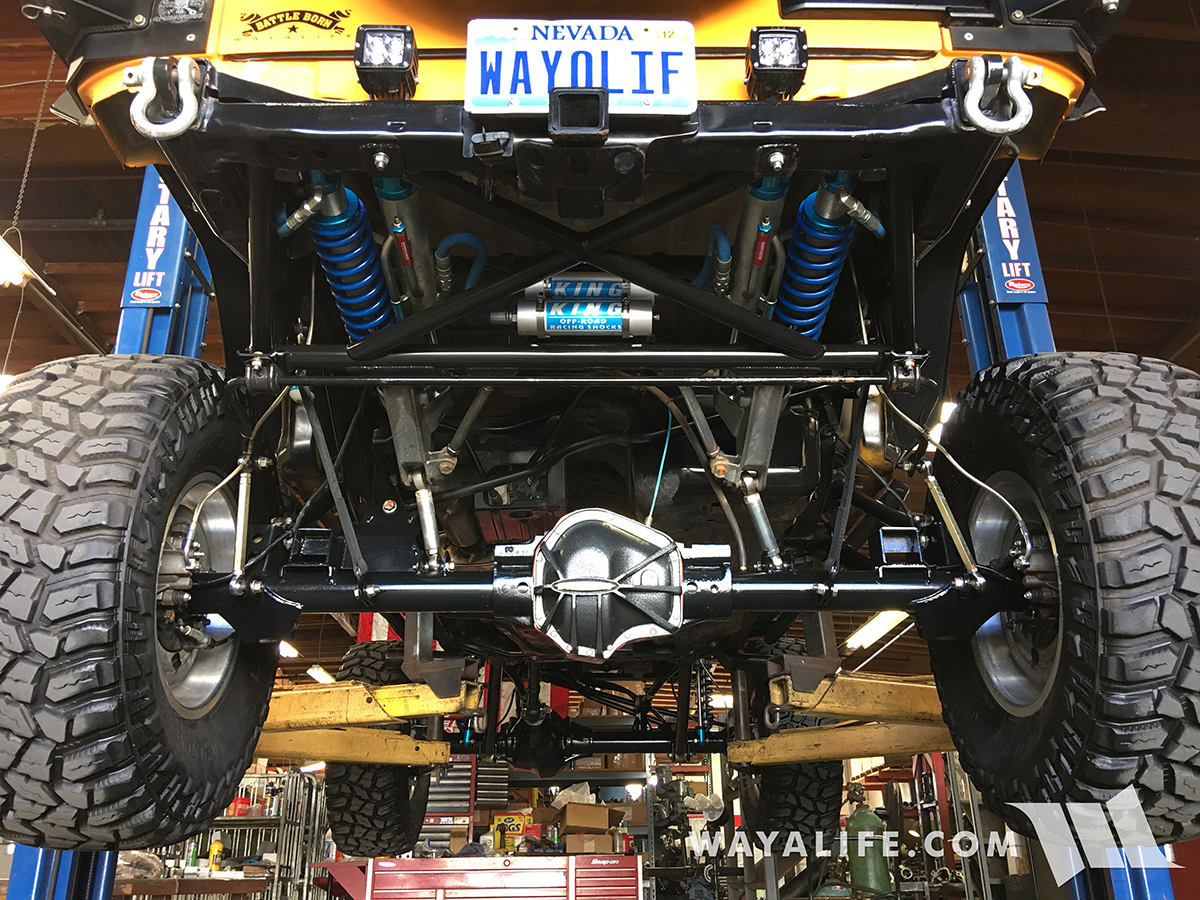

Final installation of our new 72.5" XD60 on Rubicat.

Because there really hasn't been a means to accommodate high end bead lock wheels with a greater amount of backspacing, there hasn't been a need to make them and because of it, there aren't too many options to choose from. Fortunately for us, Trail Ready does and with 5.5" of backspacing - exactly what we needed and the best part is, they're made in the U.S.A.!

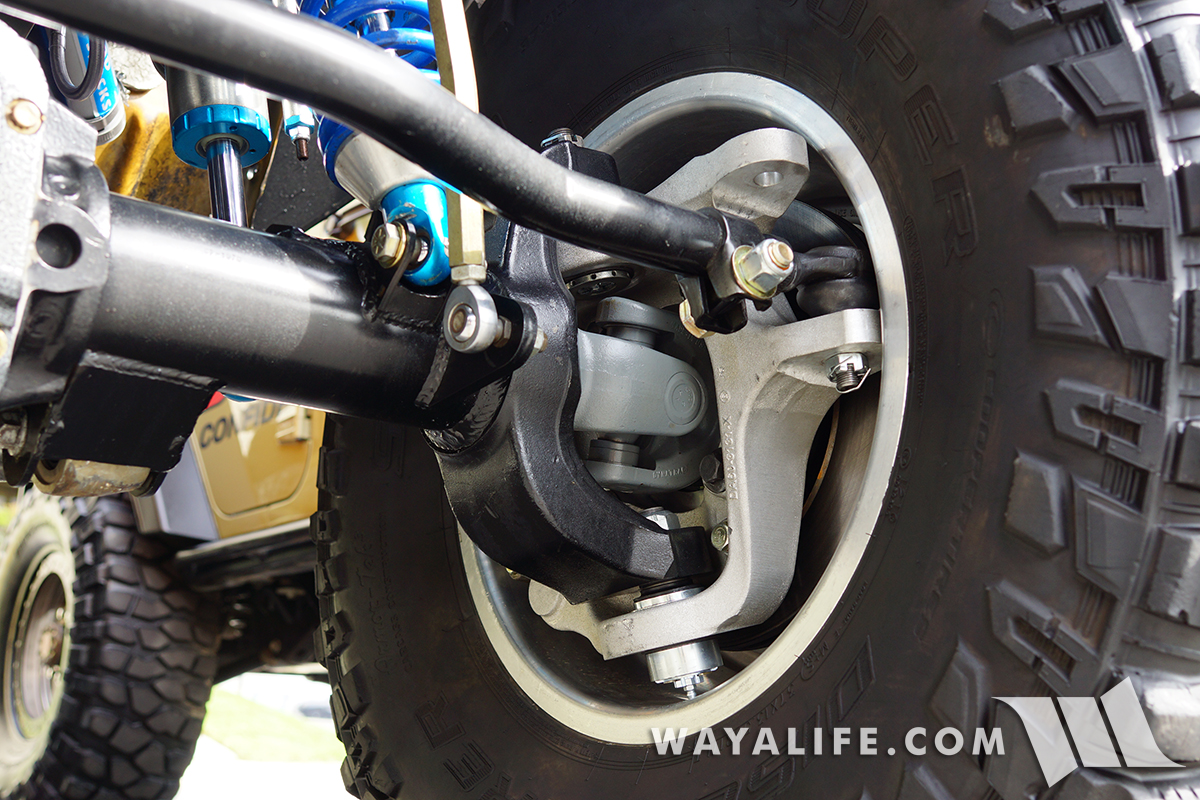

Here's a shot that shows just how well the PRO 1550 and everything installed on it is tucked well inside the Trail Ready wheel.

A few minor modifications had to be made to the bypass shock mounts to make everything work but I doubt most could even see it.

While we may have been able to run wheel spacers to help make up the difference in the rear, we decided to recycle our old ProRock 60 and have it rebuilt to a matching width.

Rubicat back on her feet again.

Look at all that clearance! Oh, and yes, a skid plate for the ram will be installed. It was left off for this photo shoot as adjustments were still being made to everything.

Close up shot of the passenger side PRO 1550 steering knuckle.

Shot of the driver side.

Time to do some fork lift flex testing to check for any rubbing or clearance issues.

Just as it was designed, the drag link just misses the frame rail even at a full bump.

Just because everyone and their mother runs big offset wheels with 4" of back spacing or less, doesn't mean it's necessarily a good idea. While pushing the center line of your wheels further out will help you to run bigger tires and without rubbing issues, you do it at the expense of increasing your scrub radius and at the cost of putting more stress on your ball joints, wheel bearings and even tie-rod. Of course, for most in the industry, that's just the way things have always been done, but for Dynatrac, it's a problem they wanted to solve. As luck would have it, Cindy and I would get a chance to help them do just that and with the assistance of Rubicat.

Bigger & Better

In addition to it's superior strength and significant weight savings, the Dynatrac PRO 1550 steering knuckle was specifically designed so that the steering axis inclination (the imaginary line you can draw through the axis of your ball joints) would meet at a point that's a lot closer to the center line of your wheel. By doing this, your wheels will pivot more instead of scrubbing as you make a turn and that alone helps to provide for much better steering and reduced stress on your tie-rod. In fact, the more back spacing you can run on a wheel (5.5" is optimal), the better everything will work especially with a set of 40" tires.

Just to give you an idea of how much bigger a Dynatrac PRO 1550 is than a factory steering knuckle, here's a side by side shot of of the two. If you can believe it, the difference between the two is only about 1.5 lbs. and this in spite of the PRO 1550's massive size.

Now, this is a side by side shot of standard PRO 60 steering knuckle on the left and a PRO 1550 on the right. As you can see, the opening is considerably wider on the PRO 1550 and this is to allow for a much bigger shaft. Also, because the PRO 1550 is made out of military grade aluminum instead of nodular iron like the PRO 60, it weighs about 8 lbs. less!

While the PRO 1550 steering knuckles alone will help improve your steering and a set of wheels with 5.5" of back spacing would make it that much better, Dynatrac understood that there are a lot of folks running coil over systems like the EVO DTD, Cindy and I included, and that this setup would prove to be a problem. To help address it, they decided to create a new version of their awesome XD60 that is wider... a LOT wider! For reference, a factory axle measures 65.5" wide and it can be difficult to run big wide tires or a coil over kit like the EVO DTD without running wheels with very little back spacing and in some cases, wheels spacers on top of them. A standard full width axle like a Dynatrac ProRock 60, XD60 or ProRock 80 will have a width of 68.5" and while the extra 3" will make it possible to run wheels with more backspacing, you'd still end up rubbing the bypass shocks on a EVO DTD setup with anything more than 3.5". This new version of the XD60 comes in a huge 72.5" width - that's a whole 4" wider than a standard full width axle and that will allow you to run a wheel with a whopping 5.5" of backspacing and without any rubbing!

If you're gonna buy a Dynatrac axle, it's always best to have one that's not only built by them but assembled by one of their technicians as well.

Gotta love the XD60 differential cover in that it not only comes with a cool o-ring but it also comes with significantly bigger bolts that get torqued on and is used to help strengthen the entire housing.

Final installation of our new 72.5" XD60 on Rubicat.

Because there really hasn't been a means to accommodate high end bead lock wheels with a greater amount of backspacing, there hasn't been a need to make them and because of it, there aren't too many options to choose from. Fortunately for us, Trail Ready does and with 5.5" of backspacing - exactly what we needed and the best part is, they're made in the U.S.A.!

Here's a shot that shows just how well the PRO 1550 and everything installed on it is tucked well inside the Trail Ready wheel.

A few minor modifications had to be made to the bypass shock mounts to make everything work but I doubt most could even see it.

While we may have been able to run wheel spacers to help make up the difference in the rear, we decided to recycle our old ProRock 60 and have it rebuilt to a matching width.

Rubicat back on her feet again.

Look at all that clearance! Oh, and yes, a skid plate for the ram will be installed. It was left off for this photo shoot as adjustments were still being made to everything.

Close up shot of the passenger side PRO 1550 steering knuckle.

Shot of the driver side.

Time to do some fork lift flex testing to check for any rubbing or clearance issues.

Just as it was designed, the drag link just misses the frame rail even at a full bump.