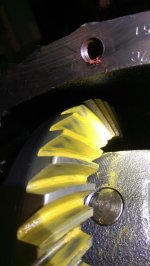

I'm in need of a little advice. Can anyone look at these pics and tell me which direction I should go next? Backlash is at .007 with this pattern. This is a D30. Also, should a D30 have a inner pinion oil slinger? Mine didn't from the factory.Thanks ahead for any help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gearing help

- Thread starter DRobson

- Start date

WJCO

Meme King

I would leave that pattern right where it's at if I were working on it. With new gears, if you can't get the drive and coast both perfect, focus more on the drive side pattern. It's more important to have the pattern centered between the crown and root rather than the toe and heel. Your pattern is centered and is pretty damn close.

As far as an inner slinger, my Dana 30 did not have one nor did I install one. It did have a rear slinger though. It also had a baffle behind the inner pinion race though. Looks like this. The embossed lip points outward towards the outboard pinion bearing when installing.

As far as an inner slinger, my Dana 30 did not have one nor did I install one. It did have a rear slinger though. It also had a baffle behind the inner pinion race though. Looks like this. The embossed lip points outward towards the outboard pinion bearing when installing.

Jody Treadway

New member

It's close, but it looks a little deep. I'd say around 0.003"- 0.005" too deep. You can tell by the distinct straight line at the bottom of the tooth. A gear set a little too deeply will generate a good bit more heat than one set more centered. On a low pinion front diff application, setting them up a hair deep is acceptable as the pattern will move up the tooth slightly under load going forward. On a HP application like yours it will move just a hair deeper under load.

To get a better read, I turn the carrier via wrench on the ring gear bolts. You can rotate it so the marking compound is approaching the pinion, then rock back and forth with the wrench. This technique will yield pattern that is much easier to read.

To get a better read, I turn the carrier via wrench on the ring gear bolts. You can rotate it so the marking compound is approaching the pinion, then rock back and forth with the wrench. This technique will yield pattern that is much easier to read.

Jody Treadway

New member

I like the "new" drive side pattern better as it is more centered. But the coast side is a bit hard to read. How are you rotating the ring and pinion? The wrench method I posted works great.

I tried the wrench method and didn't get good results. I had way too much compound so I cleaned some off. I'm spinning the yoke with a drill and putting a bit of drag on the ring gear. Here's a couple better coast side pics.

Attachments

WJCO

Meme King

Decreased the pinion shim another .005. Backlash is now .005. Keep going or is this pattern acceptable?

Pattern looks acceptable IMO (it will spread out under load), but .005 on the backlash is too tight. Hit the ring gear on each side with a deadblow hammer and recheck backlash in 3 spots . If you're still at .005, it's too tight. If you can nudge .006 out of it, you're good but .005 is too little.