If you're someone who's upgraded your Jeep JK Wrangler factory front axle with beefy Dynatrac ProRock 44, you'll find that changing out the gear oil on it is a bit different and really, a bit more old school being that the housing doesn't have a drain bolt. That being said, this step by step write-up will show you just how easy it is to do and being that it'll give you a chance to inspect everything inside, it's really a much better way to service your differential.

What You Will Need

• 13mm Socket

• 3/8″ Drive Ratchet

• Torque Wrench

• 5/16" 12-Point Socket

• Dead Blow Hammer

• Gasket Scraper

• Brake Cleaner

• Oil Catch Pan

• Paper Towels

• 2-Quarts 75W90 Gear Oil (or heavier if you tow or have a high gear ratio)

• The Right Stuff RTV by Permatex

Instructions

This is a pic of all the things you will need to service your Dynatrac ProRock 44 differential. For open differentials, limited slip differentials and factory lockers, I prefer using a good synthetic gear oil like Royal Purple.

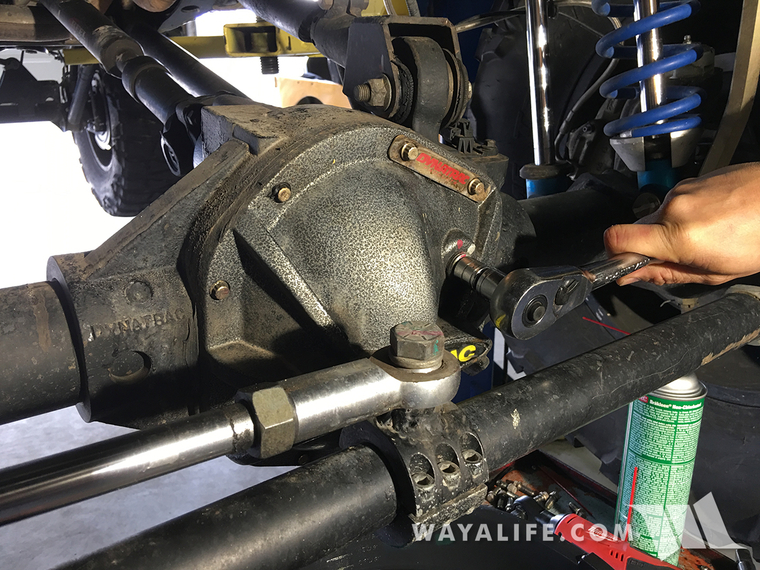

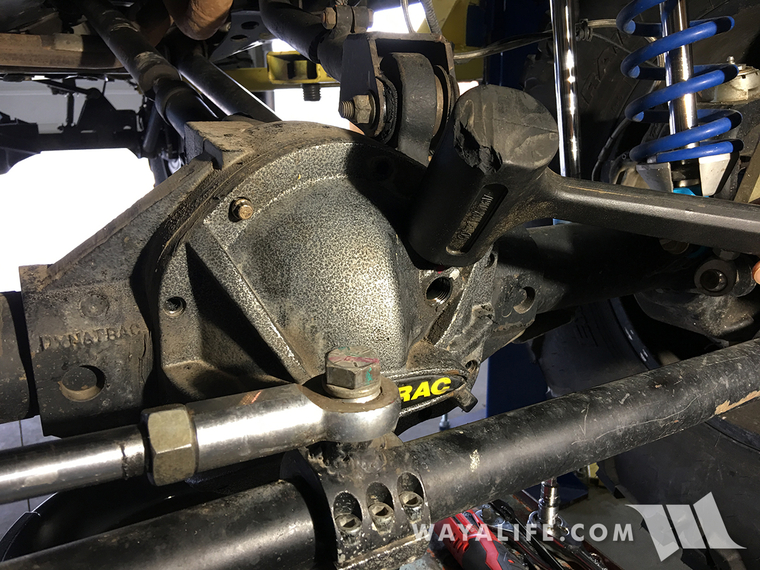

1. To begin, use the drive head of a 3/8″ Drive ratchet to remove the fill bolt from the differential cover. As you will see, I used a 1/2" drive ratchet with a 3/8" step down bit so that I could have a bit more leverage.

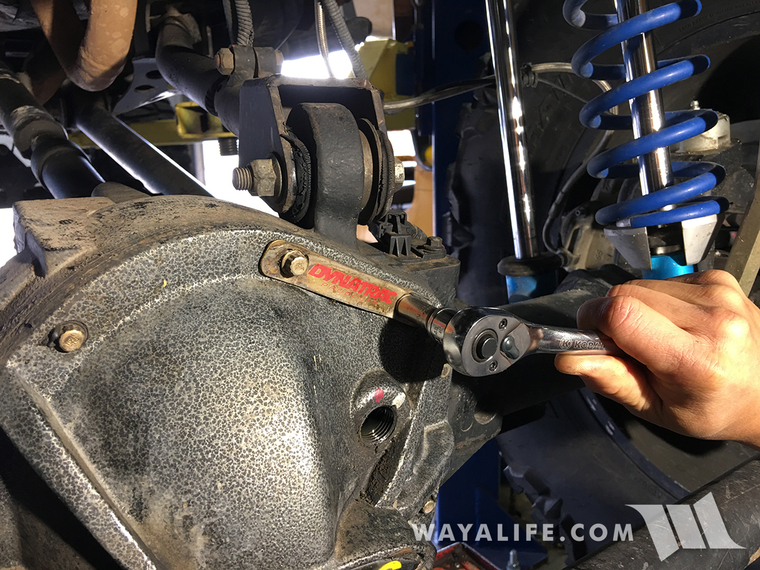

2. Using a 12-point 5/16" socket, remove all but the top bolt securing the ProRock differential cover to the housing.

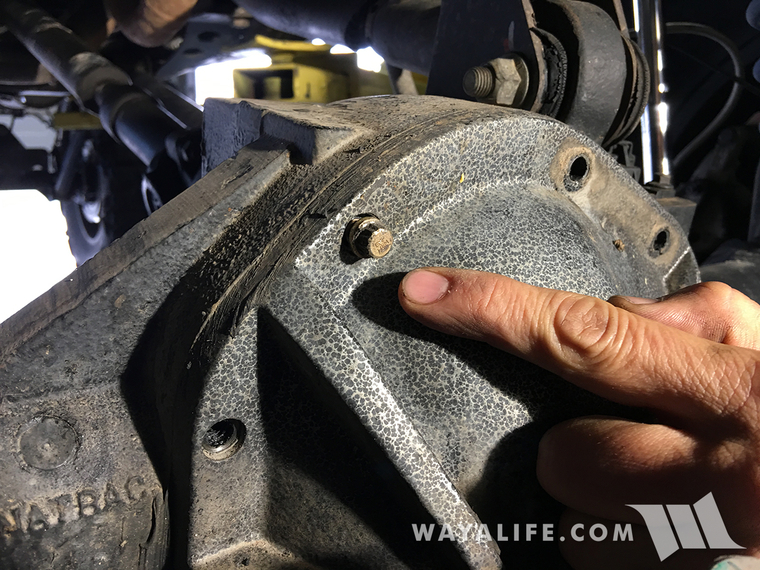

3. Loosen but do not remove the top bolt.

4. Using a dead blow hammer, strike the ProRock differential cover until it breaks free of it's RTV gasket.

5. Carefully remove your ProRock differential cover and allow the housing to drain.

6. Cover the internal components of your differential with a clean rag or paper towels. Then, using a gasket scraper or flat razor, thoroughly clean off the RTV gasket material clinging to the mating surface of the housing.

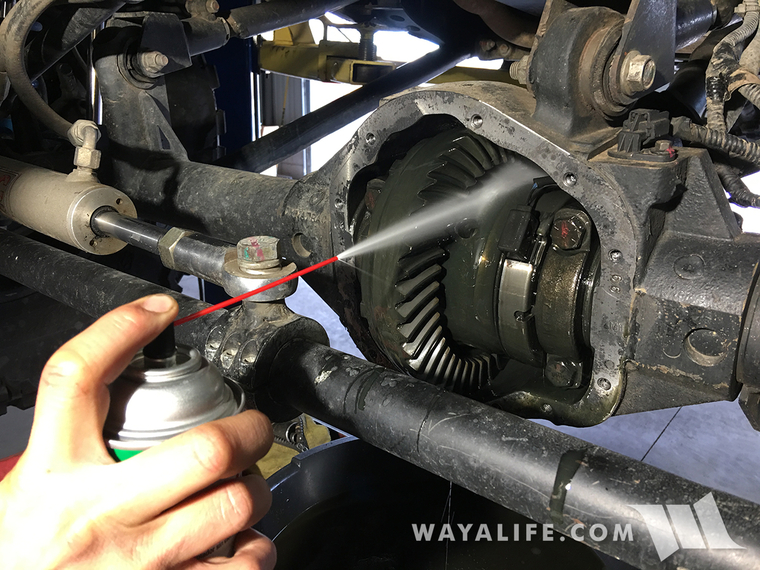

7. Remove your rag or paper towels and then thoroughly clean the internal components of your differential using some brake cleaner. Also, take some time to carefully inspect your gears for any signs of cracks, chips or missing teeth.

8. Use a gasket scraper to thoroughly clean the RTV gasket material off of the mating surface of your ProRock differential cover.

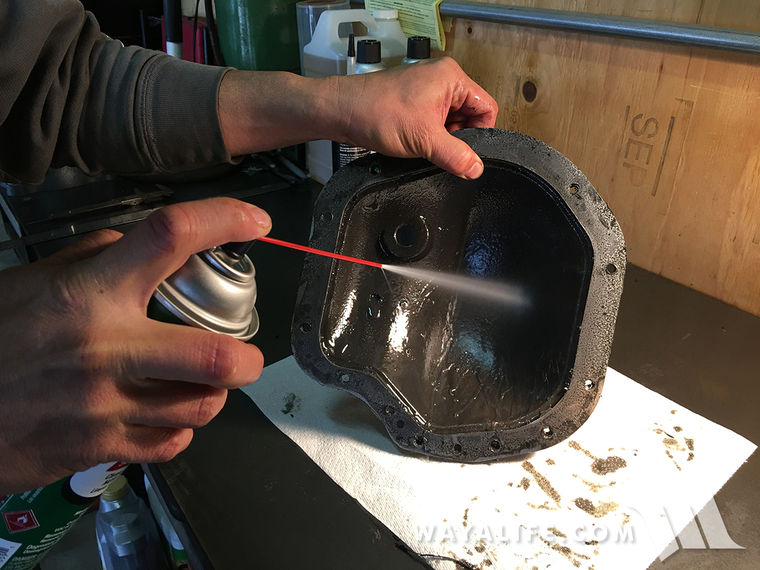

9. Using brake cleaner, thoroughly spray the inside of your ProRock differential cover as well as the mating surface and wipe it clean with a clean rag or paper towel.

10. Using a 3/16" allen wrench, remove the weep hole bold on the front of the ProRock differential cover.

11. Draw a continuous 1/4″ bead of RTV along the entire mating surface of your ProRock differential cover as shown. I would again highly recommend that you use The Right Stuff RTV by Permatex as it will provide a very strong gasket.

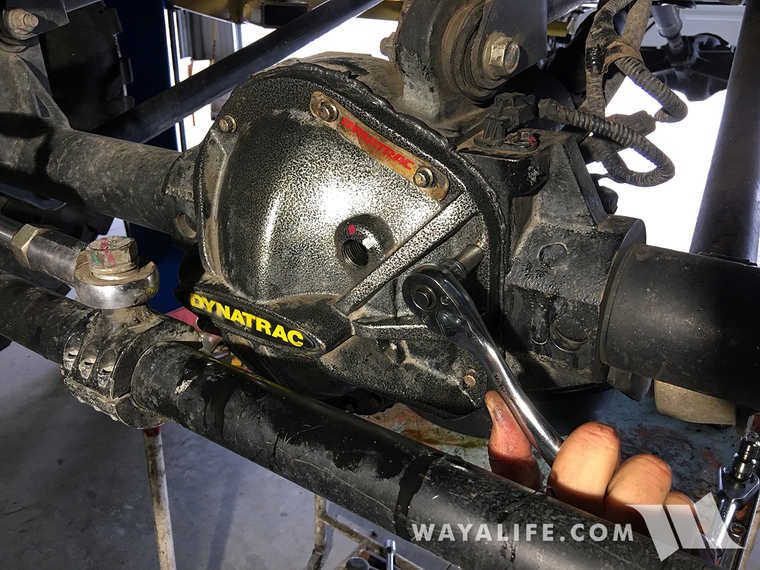

12. Carefully place your ProRock differential cover onto the differential housing making sure not to move it around too much. Then, fasten it in place using the ProRock bolts. Make sure to fasten the bolts in a criss-cross star like pattern.

13. Using a 12-point 5/16" socket, tighten the bolts down to 25-30 ft. lbs. of torque. NOTE: It is very important that you do NOT over torque these bolts and that installation of the cover should be done within 5 minutes after applying the RTV.

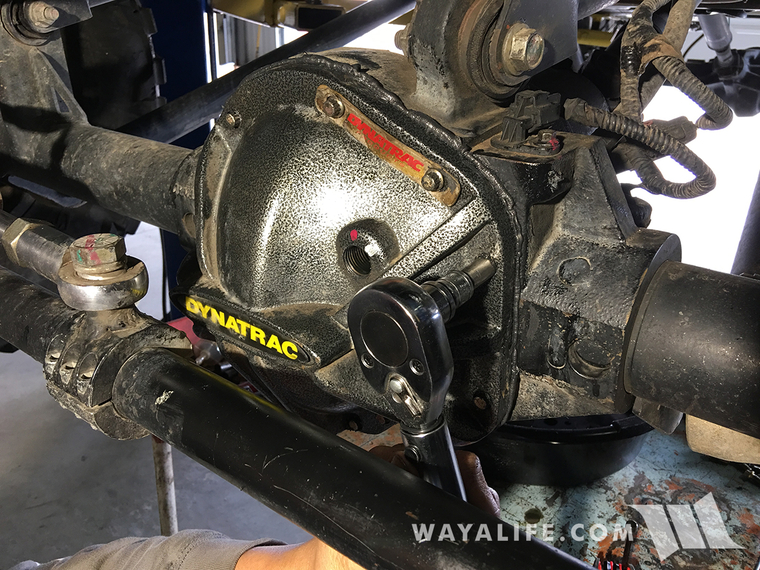

14. Fill up your differential with gear oil until it starts to ooze out of the weep hole.

15. Reinstall the weep hole bolt using a 3/16" allen wrench.

15. Using the head of a 3/8" ratchet, secure the fill bolt in place. You will need to tighten this bolt to 25 ft. lbs. of torque.

And, that’s it! Please let me know if you have any questions and don’t forget to take your used gear oil to your local recycling center (PepBoys, Autozone or the like).

What You Will Need

• 13mm Socket

• 3/8″ Drive Ratchet

• Torque Wrench

• 5/16" 12-Point Socket

• Dead Blow Hammer

• Gasket Scraper

• Brake Cleaner

• Oil Catch Pan

• Paper Towels

• 2-Quarts 75W90 Gear Oil (or heavier if you tow or have a high gear ratio)

• The Right Stuff RTV by Permatex

Instructions

This is a pic of all the things you will need to service your Dynatrac ProRock 44 differential. For open differentials, limited slip differentials and factory lockers, I prefer using a good synthetic gear oil like Royal Purple.

1. To begin, use the drive head of a 3/8″ Drive ratchet to remove the fill bolt from the differential cover. As you will see, I used a 1/2" drive ratchet with a 3/8" step down bit so that I could have a bit more leverage.

2. Using a 12-point 5/16" socket, remove all but the top bolt securing the ProRock differential cover to the housing.

3. Loosen but do not remove the top bolt.

4. Using a dead blow hammer, strike the ProRock differential cover until it breaks free of it's RTV gasket.

5. Carefully remove your ProRock differential cover and allow the housing to drain.

6. Cover the internal components of your differential with a clean rag or paper towels. Then, using a gasket scraper or flat razor, thoroughly clean off the RTV gasket material clinging to the mating surface of the housing.

7. Remove your rag or paper towels and then thoroughly clean the internal components of your differential using some brake cleaner. Also, take some time to carefully inspect your gears for any signs of cracks, chips or missing teeth.

8. Use a gasket scraper to thoroughly clean the RTV gasket material off of the mating surface of your ProRock differential cover.

9. Using brake cleaner, thoroughly spray the inside of your ProRock differential cover as well as the mating surface and wipe it clean with a clean rag or paper towel.

10. Using a 3/16" allen wrench, remove the weep hole bold on the front of the ProRock differential cover.

11. Draw a continuous 1/4″ bead of RTV along the entire mating surface of your ProRock differential cover as shown. I would again highly recommend that you use The Right Stuff RTV by Permatex as it will provide a very strong gasket.

12. Carefully place your ProRock differential cover onto the differential housing making sure not to move it around too much. Then, fasten it in place using the ProRock bolts. Make sure to fasten the bolts in a criss-cross star like pattern.

13. Using a 12-point 5/16" socket, tighten the bolts down to 25-30 ft. lbs. of torque. NOTE: It is very important that you do NOT over torque these bolts and that installation of the cover should be done within 5 minutes after applying the RTV.

14. Fill up your differential with gear oil until it starts to ooze out of the weep hole.

15. Reinstall the weep hole bolt using a 3/16" allen wrench.

15. Using the head of a 3/8" ratchet, secure the fill bolt in place. You will need to tighten this bolt to 25 ft. lbs. of torque.

And, that’s it! Please let me know if you have any questions and don’t forget to take your used gear oil to your local recycling center (PepBoys, Autozone or the like).